Exploring the Five Key Principles of Lean Thinking

Imagine a team struggling with repeated delays and wasted resources. They turn to Lean Thinking, a methodology built on five principles: value, value stream, flow, pull, and perfection. Originating from the Toyota Production System, Lean Thinking helps systems and teams across manufacturing, healthcare, services, and government achieve better results.

Industry Sector | Examples of Lean Adoption and Impact | Quantitative Highlights |

|---|---|---|

Manufacturing | Toyota, Boeing, GE, Bosch, Embraer, Braskem, China, South Korea | N/A |

Healthcare | Virginia Mason Medical Center, ThedaCare, NHS, Hospital Israelita Albert Einstein | Reduced medical errors, shorter hospital stays |

Services | Amazon, Banco do Brasil, Delta Airlines, Lean Startup Methodology | |

Government/Public | City of Cape Town, Government of Canada, Estado de São Paulo, US VA | Cape Town reduced licensing backlog by 60% |

Teams using Lean Thinking report cost savings, improved efficiency, and higher quality. These benefits come from reducing waste, streamlining processes, and engaging employees with better use of resources.

Key Takeaways

Lean Thinking helps teams improve by focusing on what customers truly value and removing waste.

The five key principles—Value, Value Stream, Flow, Pull, and Perfection—guide organizations to work smarter and faster.

Mapping the value stream reveals steps that add value and those that waste time or resources.

Creating smooth flow in processes reduces delays, cuts costs, and boosts quality and customer satisfaction.

Pull systems produce only what customers need when they need it, preventing overproduction and excess inventory.

Continuous improvement means making small, ongoing changes that lead to big gains over time.

Engaging employees in Lean practices increases motivation, innovation, and job satisfaction.

Strong leadership and clear goals are essential to start, sustain, and succeed with Lean Thinking.

Lean Thinking Overview

Definition

Lean Thinking stands as a business management framework that focuses on creating value for customers while eliminating waste. This approach organizes value-creating activities along a value stream, allowing systems and teams to deliver products and services with fewer resources. Lean Thinking does not offer a quick fix. Instead, it represents a fundamental shift in mindset and practice. Teams begin by understanding what customers truly value. They then remove non-value-adding activities and foster continuous learning. This method encourages ongoing experimentation and adaptation, aiming for perfect value with zero waste. Workers and managers collaborate to improve quality, flow, time, effort, and cost. The framework respects the humanity of all stakeholders and adapts to different industries, making it versatile for manufacturing, healthcare, services, and government.

Origins

The roots of Lean Thinking trace back to the Toyota Production System (TPS), developed in Japan during the 1940s and 1950s. Toyota faced economic challenges and resource scarcity after World War II. Engineers like Taiichi Ohno played a key role in shaping TPS. They focused on eliminating waste, improving quality, and increasing efficiency. TPS built on Henry Ford’s assembly line concepts but introduced flexibility and responsiveness. Two main pillars—Just-in-Time (JIT) and Jidoka (autonomation)—helped Toyota minimize inventory and maintain high quality. The company’s commitment to continuous improvement and management excellence earned global recognition. In 1990, the book "The Machine That Changed the World" introduced Lean Production to Western audiences. Researchers distilled TPS principles into Lean Thinking, expanding its application beyond manufacturing. Today, systems and teams in many sectors use Lean Thinking to achieve operational excellence.

Philosophy

Lean Thinking’s philosophy centers on improving efficiency and quality by eliminating waste and continuously refining processes. The five key principles—Value, Value Stream, Flow, Pull, and Perfection—guide organizations in delivering more value to customers and society. The philosophy encourages participation from everyone in the organization. Leaders act as teachers and mentors, helping others understand and apply Lean principles. The culture promotes stopping to identify root causes and solving problems through kaizen, or continuous improvement. Leadership commitment is essential for success. Lean Thinking aligns customer satisfaction with employee engagement and sustainable growth. Teams learn to identify and eliminate waste in their own work, fostering collaboration and innovation. The approach supports a long-term vision, not just short-term gains. Systems and teams that embrace Lean Thinking gain agility, efficiency, and a competitive edge. For those interested in learning more or seeking guidance, reaching out to experts can help unlock the full potential of Lean Thinking.

Five Key Principles

Value

Value stands as the foundation of Lean Thinking. Systems and teams must first define what value means from the customer's perspective. Value includes the features, quality, price, and delivery time that customers expect. Organizations focus on what customers are willing to pay for and remove anything that does not contribute to this goal.

A values-driven culture supports better outcomes. When leadership integrates shared values into strategic plans, systems and teams become more resilient and effective. For example, organizations that align their culture with respect, equity, and compassion see improved staff performance and well-being. Leaders who design interventions based on shared values create environments where employees can excel. Regular assessment and shared accountability for outcomes help maintain a strong focus on value.

Value is not defined by the producer but by the customer. Systems and teams that understand this principle can eliminate unnecessary work and deliver what truly matters.

Value Stream

After defining value, systems and teams map the value stream. This process involves visualizing every step required to bring a product or service from concept to customer. Mapping the value stream helps identify which steps add value and which create waste.

Many organizations have used value stream mapping to achieve significant improvements:

An agriculture equipment manufacturer reduced lead times and operational costs by identifying waste in the supply chain.

A biotech firm found non-value-adding activities in drug development, leading to faster cycle times.

A global pharmaceutical company discovered bottlenecks that hurt profit margins and improved their processes.

A wellness industry leader eliminated unnecessary steps, improving customer value.

A semiconductor manufacturer increased efficiency and competitiveness by overhauling value stream processes.

An aerospace components firm reduced lead times and improved product quality.

A cosmetics brand improved lead times and customer satisfaction by identifying inefficiencies.

A case study from a small manufacturing company in India showed that value stream mapping cut lead time by over 82%, reduced work-in-process inventory by 80%, and lowered finished goods inventory by 50%. These results demonstrate how mapping the value stream enables targeted waste elimination and process optimization.

Flow

Flow ensures that value-creating steps occur in a smooth, uninterrupted sequence. Systems and teams strive to remove delays, bottlenecks, and interruptions so that work progresses efficiently from start to finish.

Improving flow leads to measurable benefits across industries:

Impact Area | Documented Effects and Metrics |

|---|---|

Task Completion Time | Reduced by 40-60% through streamlined workflows and bottleneck elimination. |

Productivity | Up to 35% increase in manufacturing productivity within the first year. |

Cost Savings | 25-30% reduction in operational costs via automation, waste reduction, and error minimization. |

Quality Improvements | 50% reduction in errors and defects, leading to 30% higher customer satisfaction and 45% fewer complaints. |

Market Responsiveness | Faster product launches (40% quicker), ability to adjust production in 24-48 hours, and real-time service modifications. |

Operational Metrics | Cycle time reduction (40-60%), first-time-right rate improvement (35-45%), resource utilization increase (25-35%). |

Financial Metrics | Operating cost reduction (25-30%), revenue per employee increase (20-30%), ROI of 150-200% within first year. |

Customer Metrics | Customer satisfaction improvement (30-40%), service delivery speed increase (45-55%), retention growth (15-25%). |

Systems and teams that focus on flow can deliver products and services faster, with fewer errors and lower costs. They also become more responsive to market changes and customer needs. Lean Thinking encourages organizations to prioritize high-impact processes, analyze current workflows, and set measurable goals for improvement.

Pull

The Pull principle guides systems and teams to produce only what customers need, when they need it. Unlike traditional push systems, which rely on forecasts and often lead to overproduction and excess inventory, Pull systems respond directly to real-time demand. This approach reduces waste, improves cash flow, and increases responsiveness to market changes.

Pull systems use tools like Kanban and Just-In-Time inventory to synchronize production with actual consumption. These tools help visualize workflow, identify bottlenecks, and control work-in-process (WIP) limits. By doing so, systems and teams can balance workloads, prevent overproduction, and maintain a smooth flow of work.

Pull systems empower organizations to adapt quickly to changing customer needs and market conditions. They also help teams detect problems faster and respond with agility.

Key practices for successful Pull implementation include:

Determining TAKT time to align production rates with customer demand.

Arranging processes sequentially to enable continuous flow and reduce work-in-progress.

Applying workload leveling (Heijunka) to balance production and minimize waiting.

Using Kanban cards as Pull signals to synchronize production with consumption.

Setting explicit process policies for clarity and consistency.

Reducing changeover times with methods like SMED (Single-Minute Exchange of Dies).

Pulling batch-built parts in small lot sizes to respond dynamically to demand.

Manufacturing and service sectors have both benefited from Pull systems. For example, the Toyota Production System pioneered Pull production, leading to lower inventory costs, improved synchronization, and higher customer satisfaction. Service organizations use Pull principles to match staffing and resources with real-time demand, improving efficiency and customer experience.

Systems and teams that adopt Pull principles achieve greater operational agility, reduce risk, and enhance supply chain resilience. They also foster better supplier coordination and workload balancing. For those interested in learning more about Pull systems or seeking guidance, reaching out to experts can help unlock these benefits.

Perfection

Perfection represents the ongoing pursuit of excellence in Lean Thinking. Systems and teams strive for continuous improvement by regularly evaluating processes, setting measurable goals, and eliminating waste. The journey toward perfection never truly ends, but each step brings organizations closer to delivering maximum value with minimal resources.

Organizations achieve measurable results by adopting SMART goals and tracking key performance indicators (KPIs). These clear objectives help focus improvement efforts and make progress visible to everyone involved. When employees see the impact of their work, engagement and motivation increase, driving sustained improvement.

Continuous improvement relies on small, incremental changes that add up to significant gains over time. Delaying action in pursuit of perfection can stall progress and hinder innovation.

Successful organizations, such as Toyota and Spotify, have demonstrated the power of continuous improvement. Toyota empowers frontline workers and standardizes processes, resulting in higher efficiency and quality. Spotify uses an innovative organizational model to scale improvement efforts globally, enabling rapid innovation and alignment with strategic goals.

Key elements that support the pursuit of perfection include:

Leadership engagement and commitment to improvement.

Standardized work processes that provide a foundation for innovation.

Employee empowerment through training and clear roles.

Data-driven decision-making and accountability for results.

Systems and teams that embed continuous improvement into their culture become more adaptable and resilient. They respond effectively to changing market conditions and customer needs. Lean Thinking encourages everyone to contribute ideas and take ownership of improvements. For those seeking to build a culture of excellence, expert guidance can help accelerate progress and sustain results.

Applying Lean Thinking

Identifying Value

Systems and teams begin Lean Thinking by identifying value from the customer’s perspective. This step ensures that every activity aligns with what the customer wants and is willing to pay for. To determine value, teams follow three main criteria:

The customer must be willing to pay for the activity.

The activity must transform the product or service in some way.

The activity must be done correctly the first time.

Activities that do not meet these criteria are considered non-value-added and should be targeted for elimination. Teams specify value by product family, focusing on solving customer problems cost-effectively. They also recognize that value is subjective and can depend on context, time, and even emotional factors. Customers pay with more than money; they also invest time and reputation. Teams must understand these broader aspects to deliver true value.

Note: Assigning responsibility for each value stream to a manager helps align efforts and drive continuous improvement.

Mapping Value Stream

After identifying value, systems and teams map the value stream. Value Stream Mapping (VSM) stands as the primary tool for this process. VSM helps visualize every step required to deliver a product or service, from start to finish. Teams create three types of maps:

Current State Map: Shows existing workflows and highlights inefficiencies.

Ideal State Map: Represents a scenario with no waste, serving as a target.

Future State Map: Outlines actionable steps to move from current to ideal.

Effective mapping requires a clear scope, accurate data, and input from a diverse team. Keeping the process simple ensures clarity. Regular updates to value stream maps help sustain improvements. In practice, automotive companies have reduced cycle times by 15%, and hospitals have decreased patient wait times by 20% using VSM. Employee engagement and flexibility in adapting mapping techniques are key to success.

Creating Flow

Creating flow means ensuring that value-creating steps happen in a smooth, uninterrupted sequence. Teams in both manufacturing and service environments benefit from this approach. Best practices for creating flow include:

Aspect | Best Practices / Benefits |

|---|---|

Productivity Gains | 20-35% increase in output per worker; 40-60% reduction in cycle times |

Customer Satisfaction | On-time delivery rates above 95%; consistent quality; flexible order quantities |

Financial Benefits | 15-25% reduction in operating costs; 20-30% improvement in profit margins |

Operational Benefits | 40-60% reduction in production space; 80-90% improvement in inventory turnover |

Implementation Steps | Assess current flows, map value streams, optimize layout, train employees, integrate tech |

Teams assess current flows, identify bottlenecks, and design layouts that minimize unnecessary movement. Training and technology integration support smooth operations. In service environments, reducing delays and improving transitions also foster flow. Regular monitoring and adjustments keep processes efficient and responsive.

Establishing Pull

Establishing a pull system means producing only what customers need, exactly when they need it. Systems and teams use this approach to avoid overproduction and reduce waste. Pull systems rely on real-time demand signals, such as Kanban cards or electronic triggers, to start production or service delivery. This method helps organizations match output with actual consumption, leading to lower inventory costs and improved efficiency.

To set up a successful pull system, systems and teams follow several important steps:

Understand customer demand by analyzing patterns and aligning production with real needs.

Organize work into cells or lines and implement Kanban systems with clear Work-In-Progress (WIP) limits.

Use visual management tools, such as supermarket systems or FIFO lanes, to coordinate pull signals across different stages.

Establish buffers strategically to decouple supplying and consuming stages, triggering replenishment based on actual use.

Calculate Kanban levels by considering demand, lead time, safety stock, and supplier reliability.

Maintain strict discipline to avoid slipping into push production, even when demand fluctuates.

Monitor supplier reliability and maintain open communication to ensure predictable delivery and system stability.

Pull systems increase efficiency by producing only what is needed at the moment. They also reduce inventory levels and costs, improve product quality, and help systems and teams respond quickly to changes in demand.

However, pull systems require careful planning and excellent communication. If demand rises unexpectedly, there is a risk of stockouts. Teams must remain flexible and disciplined, always monitoring performance and making adjustments as needed. Collaboration with suppliers and regular training for staff support the ongoing success of pull systems. When systems and teams align the pull system with strategic business goals, they achieve greater responsiveness and customer satisfaction.

Continuous Improvement

Continuous improvement means always looking for ways to make processes better. Systems and teams use this principle to drive small, ongoing changes that add up to big results over time. The goal is to create a culture where everyone feels responsible for finding and solving problems.

Effective continuous improvement starts with open communication. Teams share ideas and feedback in a safe environment, which encourages innovation and risk-taking. Regular training programs help employees build new skills and stay updated on best practices. Setting clear, SMART goals gives direction and motivation, while collaboration across teams breaks down barriers and sparks creativity.

Teams use visual management tools, like Kanban boards, to track progress and make workflows transparent. Data and analytics help identify areas for improvement and measure results. Leaders play a key role by modeling adaptability, transparency, and humility. They build trust by following through on commitments and holding everyone accountable without blame.

Recognizing achievements and learning from setbacks motivates teams to keep improving. Continuous feedback loops involving employees, customers, and stakeholders ensure that improvements align with real needs.

Systems and teams that embrace continuous improvement become more adaptable and resilient. They respond quickly to challenges and deliver better value to customers. By embedding improvement into daily routines and encouraging a growth mindset, organizations create lasting change. For those interested in building a culture of excellence, reaching out to experts can provide valuable guidance and support.

Benefits of Lean Thinking

Efficiency

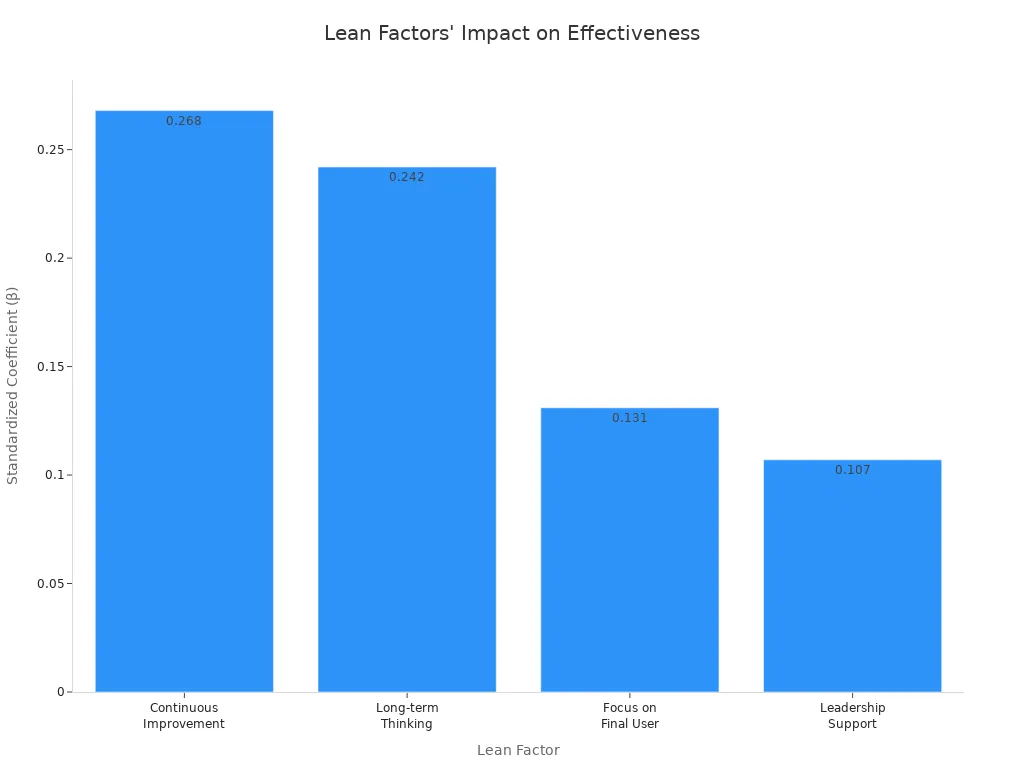

Efficiency stands as a core benefit when systems and teams adopt Lean Thinking. Organizations see measurable improvements in process effectiveness and resource utilization. A recent study in a public institution used multiple regression analysis to show that Lean factors explain 41.4% of the variance in process effectiveness. The table below highlights the impact of key Lean factors:

Lean Factor | Standardized Coefficient (β) | Significance (p-value) |

|---|---|---|

Continuous Improvement | 0.268 | < 0.001 |

Long-term Thinking | 0.242 | < 0.001 |

Focus on Final User | 0.131 | < 0.001 |

Leadership Support | 0.107 | 0.001 |

Continuous improvement has the strongest positive effect, followed by long-term thinking. These factors help systems and teams embed Lean principles into daily routines, leading to sustained efficiency gains. Focusing on the final user aligns activities with real needs, while leadership support ensures ongoing progress. Systems and teams that prioritize these factors achieve faster workflows, reduced errors, and better use of resources.

Waste Reduction

Waste reduction remains a hallmark of Lean Thinking. Systems and teams identify and eliminate eight common types of waste found across industries:

Defects: Errors such as medication mistakes in healthcare or faulty parts in manufacturing.

Transportation: Unnecessary movement of materials or people, like patient transfers or moving components between work areas.

Waiting: Delays caused by shortages, unplanned downtime, or long setup times.

Motion: Inefficient physical movements due to poor workstation layouts or equipment use.

Overproduction: Producing more than needed, leading to excess inventory.

Over-processing: Performing more work than required, often due to outdated procedures.

Inventory: Holding excess raw materials or finished goods because of poor forecasting.

Non-utilized talent: Underusing employee skills due to poor communication or lack of involvement.

Case studies show that companies like Avalign Technologies increased Overall Equipment Effectiveness by up to 50% after removing bottlenecks and reducing waste. Regular gemba walks and employee engagement help systems and teams spot and address these wastes. By focusing on waste elimination, organizations improve operational efficiency and gain a competitive edge.

Customer Value

Lean Thinking enhances customer value by aligning processes with what customers truly want. Systems and teams use several strategies to improve satisfaction and retention:

Reducing customer wait times through takt time analysis and lean queue management.

Increasing first-time resolution rates by applying error-proofing and root cause analysis.

Mapping the value stream to remove unnecessary steps in the customer journey.

Creating flow to ensure smooth, uninterrupted customer interactions.

Establishing pull systems to match production and service delivery with actual demand.

Pursuing perfection through continuous improvement, leading to ongoing enhancements in quality and value.

Companies like Amazon and Apple have improved customer experience by reducing transaction errors and wait times. Studies show that 75% of customers report long wait times negatively affect their experience. Systems and teams that focus on customer value see higher satisfaction scores and better retention rates.

Lean Thinking’s versatility extends beyond manufacturing. Healthcare, education, and service industries have adapted its principles to improve patient care, streamline workflows, and enhance value delivery. Systems and teams in these sectors achieve operational improvements and better outcomes for clients. Those interested in learning more can reach out for guidance on applying Lean Thinking in their own organizations.

Employee Engagement

Employee engagement stands as a vital benefit for systems and teams that adopt continuous improvement practices. When employees feel engaged, they show higher commitment, energy, and willingness to contribute ideas. Engaged workers often take initiative and accept change more readily. This environment leads to better performance and greater job satisfaction.

A longitudinal study in primary care settings found that employee engagement increased after the introduction of improvement practices. Workers described their experience with words like commitment, involvement, and enthusiasm. They also reported feeling empowered and more willing to participate in workplace changes. These results appeared in other healthcare studies as well. Teams with higher maturity in improvement methods showed stronger engagement and a sense of thriving. Job resources such as participation and learning opportunities played a key role in this process.

Specific practices, such as Kaizen, encourage employees to take part in problem-solving and process changes. These activities give workers more decision-making power and a sense of ownership over their work. Research highlights that when systems and teams focus on participation and learning, employees report higher well-being and satisfaction. However, not all studies agree on the impact of improvement methods on well-being. The positive effects depend on how organizations consider human factors and involve staff in meaningful ways.

Supportive leadership and effective human resource management (HRM) also play a crucial role. Leaders who create a respectful and safe environment help employees feel valued. HRM practices that foster perceived organizational support make workers feel that their contributions matter. Psychological conditions such as meaningfulness, availability, and safety at work are essential for engagement. When systems and teams provide these conditions, employees become more motivated and committed to organizational goals.

Engaged employees drive innovation and help systems and teams adapt to change. Their involvement leads to better outcomes for customers and the organization.

Organizations in healthcare, manufacturing, and services have seen these benefits firsthand. Teams that involve employees in improvement efforts report higher morale and lower turnover. They also build a culture of trust and collaboration. For those interested in boosting employee engagement, reaching out for expert guidance can help systems and teams unlock these advantages and create a thriving workplace.

Implementation Tips

Getting Started

Systems and teams should begin by building a strong understanding of core lean principles. Leaders can organize workshops or training sessions to introduce the concepts of waste elimination and customer value. Mapping the value stream comes next. This step helps teams visualize every process and identify which activities add value and which create waste.

A practical approach involves these steps:

Map the value stream to highlight each process step and distinguish value-added from waste.

Engage employees in continuous improvement. Empower them to spot inefficiencies and suggest solutions.

Apply the 5S system—Sort, Set in order, Shine, Standardize, Sustain—to organize workspaces for efficiency.

Focus on customer value by implementing a pull system. Produce only what is needed, based on real demand.

Foster a culture of learning. Offer regular training and encourage ongoing process improvement.

Tip: Align lean strategies with business objectives. Set clear goals and define success metrics to measure progress.

Overcoming Challenges

Many organizations encounter obstacles when adopting lean practices. Resistance to change often appears first. Employees may feel uncertain about new methods. Leaders can address this by communicating the benefits and involving staff in decision-making. Comprehensive training helps build confidence and skills.

Common challenges and solutions include:

Challenge | Solution |

|---|---|

Resistance to Change | Communicate benefits, involve employees, provide training |

Lack of Leadership Support | Engage leaders early, show return on investment |

Inadequate Training and Resources | Invest in training, allocate necessary resources |

Data Collection Difficulties | Train teams, use user-friendly tools |

Lack of Improvement Culture | Foster feedback, recognize achievements, integrate lean daily |

Ineffective Project Selection | Use clear criteria, prioritize with data |

Failure to Measure Results | Implement KPIs, share successes |

Scope Creep | Define clear project scopes, maintain focus |

Project Completion Issues | Use control plans, standard operating procedures |

Lack of Continuous Learning | Conduct post-project reviews, capture lessons learned |

Systems and teams can reduce resistance by appointing change champions and involving employees at every stage. A robust implementation plan with clear objectives, milestones, and timelines supports success. Continuous communication and leadership engagement remain essential.

Sustaining Improvement

Long-term success depends on maintaining momentum after initial changes. Leadership commitment and alignment ensure ongoing support for lean initiatives. Systems and teams should foster a culture that values continuous improvement and respects every individual.

Key strategies for sustaining improvement include:

Provide ongoing training and coaching so employees understand lean deeply.

Empower all team members to identify problems and implement solutions.

Make processes transparent with visual management systems and standardized work.

Recognize and reward employee contributions to build enthusiasm.

Maintain a long-term perspective, treating lean as a journey.

Adapt and improve initiatives based on feedback and performance data.

Note: Exceptional leaders coach and support teams through transformation. Systems and teams that embed improvement into daily routines become more resilient and adaptable.

Organizations that want to learn more or need guidance can reach out for expert support. Sustaining improvement requires dedication, but the rewards include higher efficiency, better employee engagement, and lasting customer value.

Systems and teams that embrace the five principles—value, value stream, flow, pull, and perfection—see lasting improvements in efficiency, quality, and engagement. Long-term studies show that organizations can reduce resources by 35% through comprehensive process analysis and employee involvement. Success depends on measuring progress, standardizing processes, and sharing achievements:

Practice | Benefit |

|---|---|

Measure Progress | Track KPIs for ongoing improvement |

Standardize Processes | Maintain consistency and prevent setbacks |

Share Success Stories | Motivate and engage the organization |

Progress matters more than perfection. Every step forward builds a stronger, more resilient organization.

FAQ

What industries can benefit from Lean Thinking?

Systems and teams in manufacturing, healthcare, services, and government all use Lean Thinking. The principles help any organization that wants to improve efficiency, reduce waste, and deliver more value to customers.

How do systems and teams start implementing Lean Thinking?

They begin by mapping their value stream and identifying waste. Training employees and setting clear goals help systems and teams build a strong foundation. Leadership support and regular reviews keep improvement efforts on track.

What tools support Lean Thinking?

Common tools include Value Stream Mapping, 5S, Kanban, and Just-in-Time. These tools help systems and teams visualize processes, organize workspaces, and match production with demand.

Tip: Start with one tool and expand as systems and teams gain experience.

Can Lean Thinking work in small organizations?

Yes. Small systems and teams often see quick results because they can adapt faster. Lean Thinking does not require large budgets or complex technology. Commitment to improvement matters most.

How does Lean Thinking improve employee engagement?

Lean Thinking encourages everyone to participate in problem-solving. Employees feel valued when systems and teams listen to their ideas. This involvement increases motivation and job satisfaction.

What are the biggest challenges in Lean implementation?

Resistance to change and lack of leadership support often slow progress. Systems and teams overcome these by communicating benefits, involving employees, and celebrating small wins.

How can systems and teams sustain Lean improvements?

They maintain momentum by training staff, using visual management, and reviewing progress regularly. Leadership commitment and a culture of continuous improvement help systems and teams achieve lasting results.

For more guidance, systems and teams can reach out to our experts for support.