Mastering Six Sigma Process Mapping for Beginners

Six Sigma Process Mapping helps organizations streamline workflows and boost operational efficiency. Process optimization steps reveal hidden bottlenecks and reduce cycle times. In a healthcare facility, managers discovered seven unnecessary actions in patient discharge paperwork. After removing these steps, discharge times dropped by 45%. Efficiency gains often reach up to 50% without sacrificing quality. Customers benefit from faster service, and hiring systems operate with fewer delays.

Key Takeaways

Six Sigma Process Mapping helps teams visualize workflows, making it easier to spot inefficiencies and improve operations.

Creating process maps fosters clear communication among team members, reducing misunderstandings and enhancing collaboration.

Regularly updating process maps ensures they reflect current practices and support continuous improvement efforts.

Identifying and removing non-value steps in workflows can lead to significant time and cost savings for organizations.

Different types of process maps, like SIPOC and flowcharts, serve unique purposes and help teams analyze processes effectively.

Involving team members who work directly with processes leads to more accurate maps and better insights for improvement.

Using simple language and clear visuals in process maps makes them accessible and useful for all team members.

Continuous improvement becomes part of the culture when teams regularly review and refine their process maps.

What Is Six Sigma Process Mapping?

Simple Definition

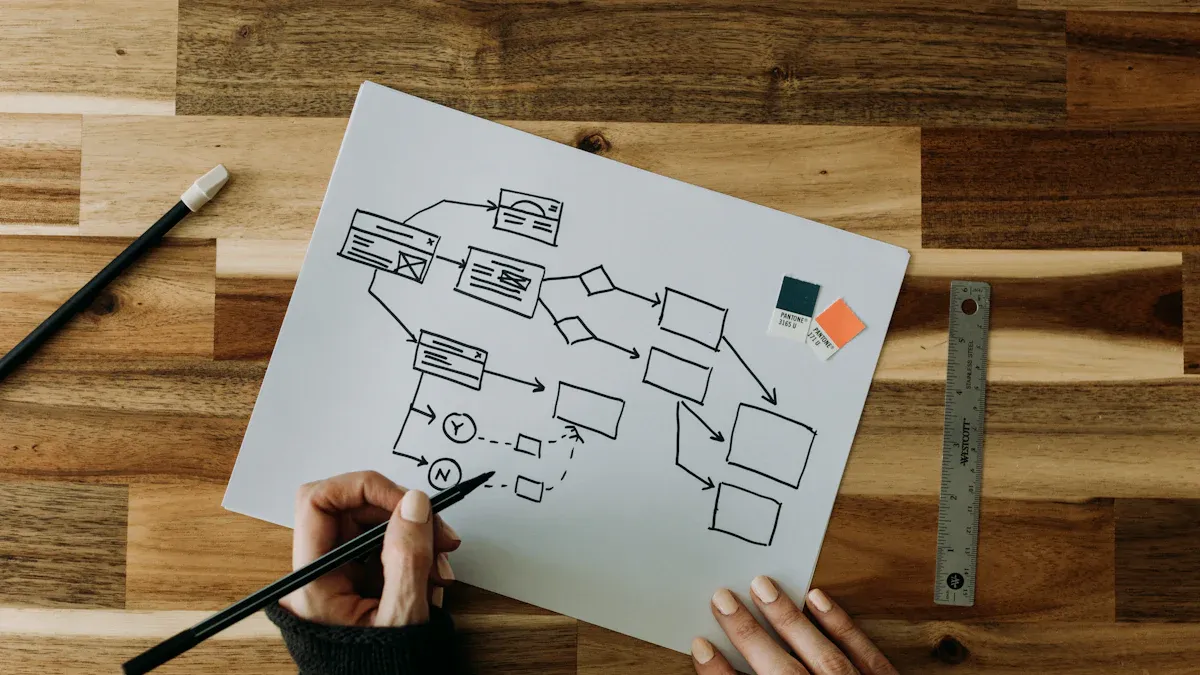

Six Sigma Process Mapping shows the steps in a business process using visual diagrams. These diagrams help teams see how work moves from start to finish. A process map uses shapes and arrows to display each action, decision, and outcome. People use these maps to understand how a product or service is created. They can also spot errors or defects in the workflow. By making the process visible, teams can find ways to improve it.

Why It Matters

Six Sigma Process Mapping plays a key role in Lean Six Sigma projects. It helps teams reduce waste and improve how work gets done. When teams create a process map, they can:

Educate people outside the process about how it works.

Compare the current process with a new one to show improvements.

Isolate steps that do not add value or slow things down.

Highlight areas that need improvement.

Build a clear understanding of the entire process.

Tip: A process map makes it easier for everyone to see where problems happen and where changes can help.

The table below shows how experts describe the benefits of process mapping:

Benefit of Process Mapping | Description |

|---|---|

Educates outsiders | Helps outsiders understand how the process works. |

Comparison | Facilitates easy comparison between current and new process maps. |

Isolates non-value steps | Enables the team to identify steps that do not add value. |

Highlights improvement areas | Points out process steps that require enhancement. |

Overall understanding | Assists the team in comprehending the entire process. |

Key Terms

Many terms appear in Six Sigma Process Mapping. Understanding these terms helps teams use process maps correctly.

Key Term | Definition |

|---|---|

Process Mapping | A tool used to visualize and improve processes, often called flowcharts or value stream maps. |

Basic flowcharts | Visual maps that provide basic process details such as inputs and outputs. |

Deployment maps | Cross-functional flowcharts that show relationships and workflow between teams, identifying bottlenecks. |

Detailed process maps | Enhanced versions of basic maps with more details on processes and subprocesses. |

High-level process maps | Overview maps showing the entire value chain of a process, including suppliers and customers. |

Value stream map | A Lean Six Sigma tool focusing on each step in product or service development, assessing value addition. |

Other important terms include:

Charter: A document that defines the context and specifics of an improvement project.

Checksheet: A form used to collect and organize data.

Common cause: Normal influences on a process that are harder to remove.

Continuous data: Variables measured on a scale, such as time or weight.

Control: The DMAIC phase for tracking and verifying process stability.

Six Sigma Process Mapping gives teams a clear picture of how work happens. It supports better decisions and helps organizations reach their goals.

Benefits of Six Sigma Process Mapping

Process Understanding

Six Sigma Process Mapping gives teams a clear view of how work flows within an organization. Visual diagrams help everyone see each step, making it easier to spot confusion or missing information. When teams map out a process, they often find steps that do not add value or cause delays. This approach helps people understand their roles and responsibilities.

Visual representations of workflows enhance communication among stakeholders, ensuring alignment on process objectives.

Process mapping helps identify gaps in understanding, such as misaligned expectations or unclear responsibilities.

Discussions prompted by process mapping clarify the necessity of each step, ensuring that every action adds value.

Enhancing understanding of existing workflows leads to significant operational improvements.

Process mapping fosters a culture of collaboration and transparency within teams.

Transparency ensures that everyone understands their role, promoting accountability and reducing errors.

Teams that use process maps often discover hidden problems and improve how they work together.

Communication

Clear communication stands as a key benefit of process mapping. When teams use diagrams, they can share information quickly and accurately. Everyone sees the same picture, which reduces misunderstandings. New employees can learn processes faster because they have a visual guide.

Process maps make it easier for people from different departments to talk about their work.

Diagrams help managers explain changes or improvements to staff.

Teams can use process maps during meetings to solve problems together.

A shared process map acts as a common language for everyone involved.

Waste Reduction

Organizations use process mapping to find and remove waste. Waste includes extra steps, delays, or errors that do not help the customer. By making each step visible, teams can decide which actions are necessary and which are not.

General Electric's Six Sigma program generated over $12 billion in savings over five years, with a 62% reduction in scrap rates and a 34% improvement in first-pass yield in its aircraft engine division.

Honeywell reduced invoice processing time by 50% and eliminated over $2 million in annual rework costs through Six Sigma.

Virginia Mason Medical Center achieved a 75% reduction in medication administration errors by redesigning pharmacy workflows using Six Sigma methodologies.

A manufacturing firm reduced defects from 4,500 DPMO (approximately 3.2σ) to 500 DPMO (approximately 4.8σ), leading to significant cost savings and enhanced product reliability.

Teams that use process mapping often see faster workflows and fewer mistakes. These improvements save time and money while increasing customer satisfaction.

Continuous Improvement

Continuous improvement stands at the heart of Six Sigma process mapping. Teams use process maps to see every step in their workflow. This visual approach helps them spot problems and find better ways to work. When teams map out a process, they can quickly identify steps that slow things down or cause errors. Over time, this leads to steady progress and higher quality.

Six Sigma process mapping supports continuous improvement in several ways:

Teams gain a clear picture of how work flows from start to finish. This makes it easier to find inefficiencies.

Visual diagrams help teams focus on facts, not opinions. They can see where waste occurs and where changes will have the most impact.

Companies use process maps to track changes over time. They can compare old and new maps to measure progress.

The DMAIC framework—Define, Measure, Analyze, Improve, Control—guides teams through each stage of improvement. Process maps play a key role in every phase.

Many organizations have used Six Sigma process mapping to drive ongoing improvement. For example, manufacturing companies often use process maps to reduce defects and improve product quality. Healthcare providers use them to streamline patient care and reduce wait times. Service organizations rely on process maps to improve customer satisfaction and cut unnecessary steps.

Teams that update their process maps regularly can respond quickly to new challenges. They can spot new problems as they arise and make changes before small issues become big ones.

Continuous improvement does not happen by accident. Teams must review their process maps often. They should ask questions such as:

Are there steps that no longer add value?

Have new bottlenecks appeared?

Can technology help automate or speed up certain actions?

By answering these questions, teams keep their processes fresh and effective. They avoid falling back into old habits that waste time or resources.

A process map acts as a living document. It grows and changes as the team learns more about their work. This approach encourages everyone to look for better ways to do things. Over time, small improvements add up to big gains in efficiency and quality.

Continuous improvement becomes part of the organization's culture when everyone uses process maps to guide their work.

Types of Process Maps

Understanding the different types of process maps helps teams choose the right tool for each situation. Each map offers a unique way to visualize and improve business processes. The table below highlights the main differences among the most common process maps in Six Sigma:

Type of Diagram | Description |

|---|---|

SIPOC Diagram | Provides a high-level overview of a process, including Suppliers, Inputs, Process, Outputs, and Customers. |

Flowchart | Visual representation of a process, detailing inputs and outputs in a straightforward manner. |

Value Stream Map | Focuses on the steps required to deliver a product or service, emphasizing value-added activities. |

Swimlane Diagram | Illustrates how a process flows across different teams, identifying roles and responsibilities. |

SIPOC Diagram

Purpose

A SIPOC diagram gives teams a broad view of a process. It stands for Suppliers, Inputs, Process, Outputs, and Customers. This map helps teams see the big picture before diving into details. SIPOC diagrams clarify who provides what, what resources the process needs, the main steps, the results, and who receives those results.

Key components of a SIPOC diagram include:

Suppliers: The sources that provide inputs for the process.

Inputs: The resources or materials needed for the process to work.

Process: The main steps that make up the process.

Outputs: The results or products created by the process.

Customers: The people or groups who receive the outputs.

Component | Description |

|---|---|

Suppliers | |

Inputs | The resources required for the process to function. |

Process | The high-level steps involved in the process. |

Outputs | The results produced by the process. |

Customers | The recipients of the outputs or those who benefit from the process. |

SIPOC diagrams help teams agree on process boundaries and understand the flow from start to finish.

When to Use

Teams use SIPOC diagrams at the beginning of a project. These diagrams work best when a team needs to define or clarify a process. SIPOC diagrams also help when teams want to communicate a process to people who are not familiar with it. They set the stage for more detailed mapping later.

Flowchart

Symbols

Flowcharts use standard symbols to show each step in a process. These symbols make it easy to follow the flow of work.

Flowline: Shows the direction of the process.

Terminator: Marks the start or end of the process.

Process: Represents a single step or action.

Comment: Adds extra information about a step.

Decision: Indicates a choice or branching point.

Stored data: Shows where data is kept.

Input/Output: Marks where data enters or leaves the process.

Document: Represents a document used or produced.

Delay: Shows a planned wait or pause.

Manual input: Indicates data entered by hand.

Applications

Teams use flowcharts to break down processes into clear, simple steps. Flowcharts help identify where problems or delays occur. They work well for training, troubleshooting, and improving existing workflows. Flowcharts also make it easier to explain processes to new team members or stakeholders.

Value Stream Map

Focus

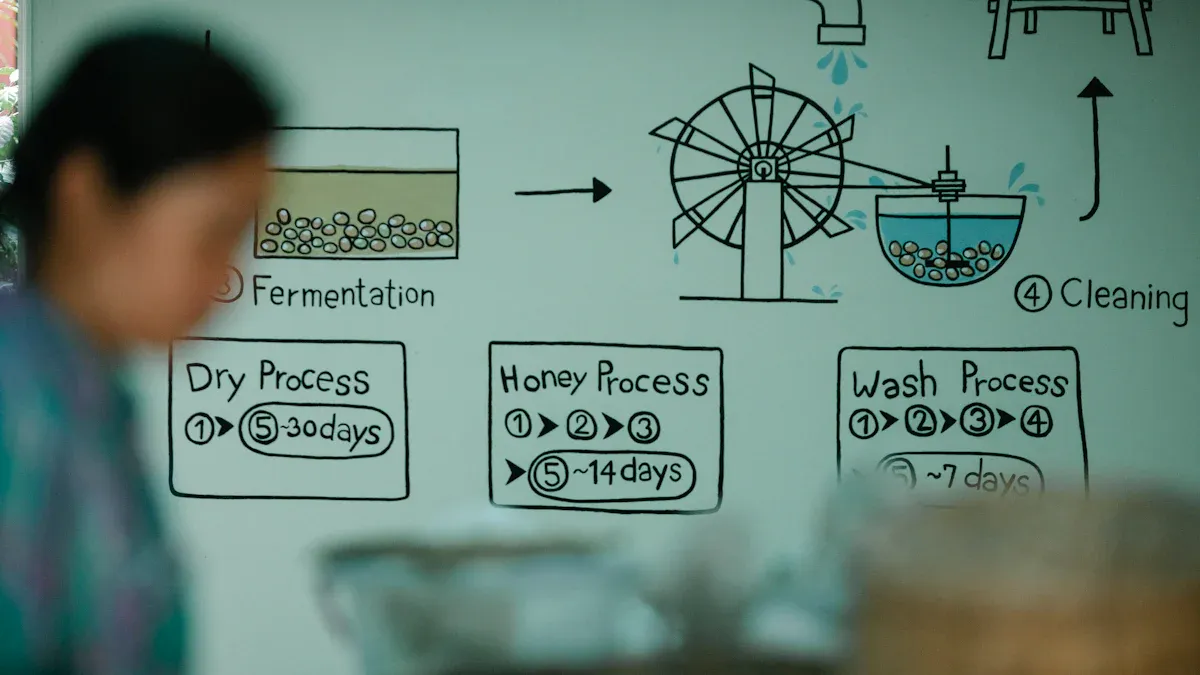

A value stream map (VSM) highlights every step needed to deliver a product or service. This map focuses on value-added activities and helps teams see where waste occurs. VSMs visualize the flow of materials and information, making it easier to spot bottlenecks and inefficiencies.

Use Cases

Teams use value stream maps to improve productivity and reduce waste. The process starts by mapping the entire value stream. Next, teams identify areas with delays or unnecessary steps. They then focus on optimizing these high-impact areas. VSMs work well in manufacturing, healthcare, and service industries where efficiency matters.

Value stream maps reveal delays and redundancies, allowing teams to streamline operations and boost performance.

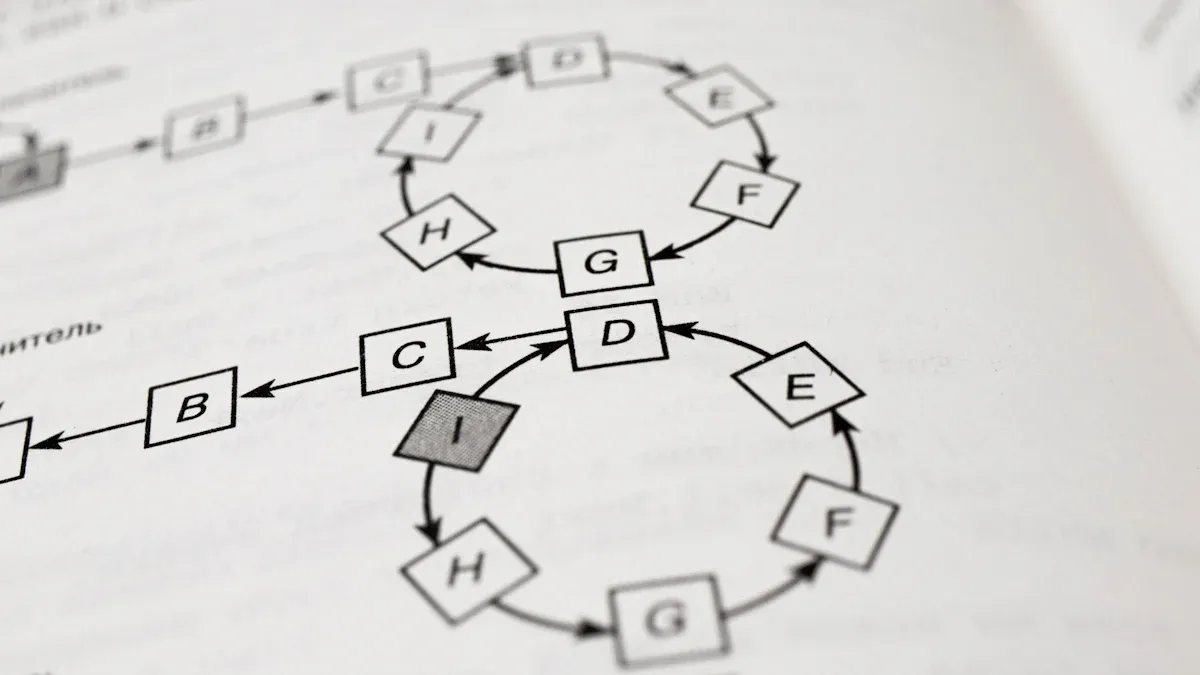

Swimlane Diagram

Swimlane diagrams help teams visualize complex processes by dividing them into lanes. Each lane represents a role, department, or group. This structure makes it easy to see who is responsible for each task. Teams use swimlane diagrams to clarify responsibilities and prevent confusion. The diagram shows how tasks move across different roles, highlighting handoffs and interactions.

Roles

Swimlane diagrams organize processes by assigning lanes to specific roles. Each lane displays the actions performed by that role. This approach helps teams understand who does what at each stage. The diagram also shows how tasks pass from one role to another. Teams can spot gaps or overlaps in responsibilities.

The table below lists typical roles found in swimlane diagrams:

Role | Description |

|---|---|

Project Managers | Oversee processes involving multiple teams, visualizing workflows and tracking progress. |

Business Analysts | Gather and analyze business requirements, documenting and improving processes. |

Operations Managers | Oversee cross-functional workflows, ensuring efficiency and clarity in responsibilities. |

General Contractors | Manage sequences of tasks in construction projects, aligning teams and ensuring task completion. |

Professional Services | Use diagrams for client engagement, ensuring understanding of responsibilities and timelines. |

Teams often use swimlane diagrams to organize processes into lanes for different roles or departments. This visual structure distinguishes responsibilities and clarifies accountability for each task. Swimlane diagrams help prevent confusion and enhance accountability in workflows.

Swimlane diagrams make it clear who owns each step. Teams can quickly identify bottlenecks or missed handoffs.

Best Use

Swimlane diagrams work best for processes that involve multiple roles or departments. They help teams track tasks as they move across different groups. This makes swimlane diagrams ideal for cross-functional projects, onboarding workflows, and service delivery processes.

Teams use swimlane diagrams in several ways:

Mapping out customer service workflows that involve agents, supervisors, and technical support.

Visualizing project management tasks that require coordination between design, engineering, and quality assurance.

Documenting onboarding processes where human resources, IT, and training teams must work together.

Improving healthcare workflows by showing how nurses, doctors, and administrative staff interact.

Swimlane diagrams also help teams spot inefficiencies. When a process has too many handoffs or unclear responsibilities, the diagram highlights these issues. Teams can then redesign the workflow to reduce delays and improve communication.

Teams that use swimlane diagrams gain a better understanding of their processes. They can assign tasks more effectively and ensure everyone knows their role.

Swimlane diagrams provide a clear, organized view of complex workflows. Teams use them to clarify responsibilities, streamline operations, and improve accountability. This tool supports better communication and helps organizations deliver consistent results.

Six Sigma Process Mapping Steps

Define Scope

Defining the scope sets the foundation for any process mapping effort. Teams must clearly outline where the process begins and ends. This step helps everyone understand the boundaries of the process under review. By establishing these limits, teams avoid unnecessary details and keep the focus on the most important parts. A well-defined scope prevents confusion and ensures that the mapping exercise remains manageable.

Identify the starting point of the process.

Determine the ending point.

Set clear boundaries to avoid including unrelated steps.

Agree on the level of detail needed for the map.

A clear scope helps teams stay on track and ensures that everyone understands the process being mapped. This step also makes it easier to measure improvements later.

Tip: Teams should write down the scope before moving to the next step. This written record keeps everyone aligned.

Identify Steps

After defining the scope, teams move on to identifying each step in the process. This stage involves gathering information about what happens from start to finish. Teams often use brainstorming sessions to list all actions, decisions, and outputs. They also consider who supplies inputs and who receives outputs.

Name the process and confirm its boundaries.

Identify where the process starts and stops.

List all outputs, considering what the customer needs.

Match each output to specific client requirements.

Identify suppliers who provide necessary inputs.

List every input, even those that seem minor.

Map out 5–7 high-level steps that make up the current process.

Teams may use tools like value stream maps, SIPOC diagrams, or swimlane diagrams to help visualize these steps. Each tool offers a different perspective, making it easier to capture all important actions and roles. Teams often compare the current process with a potential new one to spot areas for improvement.

Note: Teams should question each step to see if it adds value. Removing unnecessary actions leads to a more efficient process.

Sequence Actions

Sequencing actions ensures that the process map follows a logical flow. Teams arrange each step in the order it occurs. This sequence helps everyone understand how work moves from one stage to the next. Using standard symbols and clear labels makes the map easy to read.

Use flowchart symbols to represent actions, decisions, and outcomes.

Label each step clearly to avoid confusion.

Define the objectives for the mapping process to maintain focus.

Build a diverse team to include different viewpoints and expertise.

Map the current state to document how things work now.

A well-sequenced process map highlights where delays or errors might occur. Teams can then target these areas for improvement. Sequencing also helps visualize the flow of inputs, actions, and outputs, which is a key part of Six Sigma Process Mapping.

Teams that carefully sequence actions create maps that are easy to follow and useful for training or analysis.

Document Process

Documenting the process creates a clear and lasting record of how work happens. Teams use this step to turn their process map into a useful guide for everyone involved. A well-documented process helps new team members learn quickly and supports ongoing improvements.

Teams follow several best practices when documenting a process:

Plan before you map

Teams start by setting the scope and clarifying the goal. They decide what the process covers and what they want to achieve. This planning step keeps the documentation focused and relevant.Build your map with intention

Teams often work backward from the desired outcome. They look for ways to simplify each step. By removing unnecessary actions, they make the process easier to follow. Teams use clear symbols and labels so everyone can understand the map.Review and refine

Teams check the process map for accuracy. They look for alternate paths or exceptions that might occur. This review ensures the documentation matches real-world situations.

A good process document includes:

A title and date for easy reference.

A list of team members who helped create the map.

A clear description of the process scope.

Visual diagrams, such as flowcharts or swimlane diagrams.

Step-by-step instructions for each action.

Notes about decisions, inputs, and outputs.

Tip: Teams should use simple language and avoid jargon. Clear documentation helps everyone understand the process, even if they are new to the team.

Documenting the process also supports training and quality control. When everyone follows the same steps, the team can deliver consistent results. Over time, teams can update the documentation as they find better ways to work.

Review and Improve Your Map

Team Involvement

Successful process mapping depends on the active participation of systems and teams. When team members who work directly with the process join the mapping effort, they bring valuable insights. Their experience helps capture the real steps, not just what appears in manuals. Involving the right people leads to more accurate and effective maps. Clients at systems and teams often see better results because they include employees from every stage of the process.

The table below shows how team involvement improves process mapping:

Key Aspect | Explanation |

|---|---|

Including team members who are directly engaged in the process ensures valuable insights are captured. | |

Visualize and Understand Processes | Process maps help create a shared understanding of the steps and their interconnections. |

Identify Waste and Inefficiencies | Mapping allows teams to spot redundancies and bottlenecks, leading to streamlined processes. |

When everyone shares their knowledge, the process map becomes a true reflection of daily work. This shared understanding helps teams find ways to improve and avoid repeating mistakes.

Spot Gaps

Spotting gaps in a process map means looking for missing steps, unclear handoffs, or weak controls. Systems and teams use several methods to find these issues. They analyze data, review metrics, and ask employees for feedback. Not every process needs a complete overhaul. Sometimes, small changes in the most impactful areas lead to big improvements.

Targeted improvements often work better than changing everything at once.

Teams combine data analysis with employee feedback to find the best places to improve.

Process analysis helps identify performance breakdowns by examining data, metrics, and workflow mapping.

Employee insights reveal daily roadblocks that numbers alone may not show.

The likelihood of failure and detection assessment is an opportunity to scrutinize existing process controls and detection mechanisms critically. Through this analysis, project teams can identify gaps or weaknesses in current detection methods, enabling them to strengthen controls where needed and prioritize efforts towards enhancing detection capabilities for high-risk failure modes.

By using these methods, clients at systems and teams can focus their efforts where they will have the greatest impact.

Update Regularly

A process map should not remain static. Systems and teams must review and update their maps regularly. Changes in technology, staff, or customer needs can make old maps outdated. Regular updates ensure the map reflects current practices and supports ongoing improvement.

Teams can follow these steps to keep their maps current:

Schedule regular reviews, such as every quarter or after major changes.

Gather feedback from everyone involved in the process.

Compare the map to actual workflows and adjust as needed.

Document any changes and share the updated map with all team members.

Six Sigma Process Mapping works best when teams treat their maps as living documents. This approach helps organizations respond quickly to new challenges and maintain high performance.

Common Pitfalls to Avoid

Even with the best intentions, teams can fall into common traps when creating Six Sigma process maps. Recognizing these pitfalls helps organizations build maps that truly support improvement.

Overcomplicating

Many teams try to capture every detail in their process maps. They may use too many symbols, colors, or technical terms. This approach often leads to confusion and makes the map hard to use. Overcomplicated maps can discourage team members from using them in daily work.

Teams sometimes aim for perfect documentation instead of a practical tool. This can result in long workshops and disengaged stakeholders.

Including excessive details or complex symbols often leads to misunderstandings and slows down decision-making.

Simple language and a limited set of symbols keep maps clear and easy to follow.

Tip: Focus on the main steps and use clear, simple visuals. A process map should help teams work better, not make things harder.

Missing Steps

Leaving out steps in a process map can cause serious problems. When teams skip actions or decisions, they risk miscommunication and incomplete understanding. This can lead to mistakes, delays, or even safety issues.

Key Findings | Implications on Process Outcomes |

|---|---|

Missing steps in process mapping lead to oversimplification and miscommunication. | This can impact patient care and safety. |

Different types of process maps (sequential vs. hierarchical) influence the identification of risks. | Improvement efforts may vary based on the representation used. |

Coordination across organizational boundaries is often not captured in process maps. | Risks may emerge outside the defined boundaries, affecting overall process outcomes. |

Teams should involve subject matter experts and those who work directly with the process. This helps ensure every important step appears in the map. Failing to capture all relevant data or information can weaken the value of the process map.

Note: Always validate the process map with team members to catch missing steps before finalizing.

Not Reviewing

A process map is not a one-time project. Teams must review and update their maps regularly to keep them useful. Changes in staff, technology, or customer needs can make old maps outdated.

Regular updates ensure the map matches current workflows and supports continuous improvement.

Neglecting to update process maps can lead to errors and missed opportunities for better performance.

Teams should treat process maps as living documents, revisiting them after major changes or at set intervals.

Teams that review their process maps often find new ways to improve and adapt to changing conditions.

By avoiding these pitfalls, organizations can create process maps that drive real improvement and lasting results.

Six Sigma process mapping gives teams a clear path to better performance. Teams use different map types to visualize workflows, align goals, and drive improvement. The table below highlights key takeaways:

Key Takeaway | Description |

|---|---|

Visualization | Teams see workflows, spot waste, and boost efficiency. |

Alignment | Clear maps connect daily work to business goals. |

Digital Tools | Digital mapping speeds updates and supports lasting change. |

Root Causes | Detailed steps reveal root causes for long-term success. |

Map Types | SIPOC, flowcharts, and swimlanes serve unique roles. |

Continuous Improvement | Regular reviews keep workflows accurate and effective. |

Collaboration | Teamwork and management support drive results. |

Daily Integration | Mapping in daily routines maintains high performance. |

Teams that use Six Sigma mapping see real benefits:

DMAIC improves quality and efficiency.

Fewer defects and better customer satisfaction.

Structured steps solve complex problems.

Success comes from clear goals, regular tracking, and team collaboration. Beginners should define scope, sequence steps, review maps, and look for pain points. For more guidance, readers can reach out to the team for support.

FAQ

What is the main goal of Six Sigma process mapping?

Six Sigma process mapping helps teams visualize each step in a workflow. The main goal is to find areas for improvement, reduce waste, and increase efficiency. Teams use these maps to understand how work happens and to make better decisions.

How does a process map differ from a flowchart?

A process map shows the sequence of steps in a process. A flowchart is a type of process map that uses symbols to represent actions, decisions, and outcomes. All flowcharts are process maps, but not all process maps use flowchart symbols.

Who should participate in creating a process map?

Teams should include people who work directly with the process. Managers, team members, and subject matter experts all provide valuable insights. Involving different roles ensures the map reflects real workflows and uncovers hidden issues.

How often should teams update their process maps?

Teams should review and update process maps regularly. Schedule reviews after major changes or at least once a year. Regular updates keep the map accurate and help teams respond to new challenges.

Can process mapping help small businesses?

Yes, small businesses benefit from process mapping. Simple diagrams help teams find bottlenecks, reduce errors, and improve customer service. Even basic maps can lead to big improvements in efficiency.

What tools do teams use for process mapping?

Teams often use software like Microsoft Visio, Lucidchart, or even paper and sticky notes. The choice depends on the team's needs and the complexity of the process. Digital tools make it easier to update and share maps.

Why is it important to avoid overcomplicating a process map?

Overcomplicated maps confuse team members and slow down improvement efforts. Simple maps highlight the most important steps. Teams work better when they can easily understand and use the process map.

What is a SIPOC diagram used for?

A SIPOC diagram gives a high-level overview of a process. It shows Suppliers, Inputs, Process, Outputs, and Customers. Teams use SIPOC diagrams to define process boundaries and clarify who provides and receives each part of the workflow.