Understanding Process Improvement Methodologies and Their Benefits

You use process improvement methodologies to analyze and refine how your organization works. These approaches help you focus on optimization steps that streamline tasks and boost results. Recent industry studies show that applying a methodology for process improvement raises efficiency and quality, making your operations more reliable. When you improve a process, you address challenges and blend new technology with proven methods. You build stronger connections with customers and create value that lasts.

Key Takeaways

Process improvement methodologies help organizations analyze and optimize operations for better efficiency.

Common methodologies include Six Sigma, Lean, TQM, and PDCA, each focusing on different aspects of improvement.

Using Six Sigma can significantly reduce defects and improve quality through a structured approach.

Lean methodology emphasizes waste elimination, leading to faster processes and higher customer satisfaction.

Total Quality Management (TQM) fosters a culture of quality across the organization, enhancing teamwork and communication.

The PDCA cycle provides a simple framework for continuous improvement through planning, doing, checking, and acting.

Kaizen encourages small, daily improvements, creating a culture of ongoing enhancement and employee engagement.

Choosing the right methodology depends on your organization's goals, culture, and the complexity of processes.

What Are Process Improvement Methodologies?

Definition

You encounter process improvement methodologies as structured frameworks that help you analyze and optimize how your organization operates. These approaches guide you through a series of steps that reveal inefficiencies and highlight opportunities for growth. When you use a methodology for process improvement, you rely on proven systems that make your work more effective. You can find many recognized methodologies in business literature, including Six Sigma, Lean, PDCA cycle, Kaizen, Total Quality Management (TQM), Theory of Constraints, 5S, SIPOC analysis, process mapping, value stream mapping, Kanban, and business process automation.

Six Sigma, for example, began at Motorola and now appears in many industries. It focuses on measuring defects and improving quality. Within Six Sigma, you use DMAIC to enhance existing processes and DMADV to develop new ones. Lean principles help you reduce costs by eliminating waste, and you can apply them in any organization, not just manufacturing. The Theory of Constraints helps you identify and improve the main limiting factor that blocks your goals.

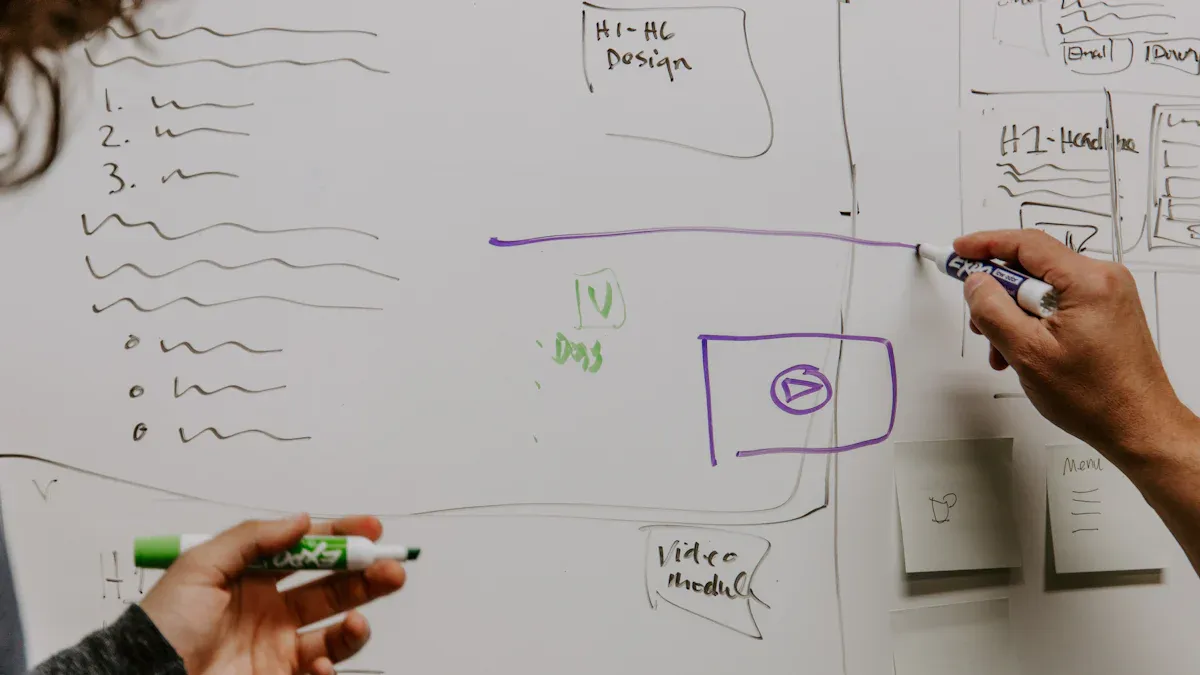

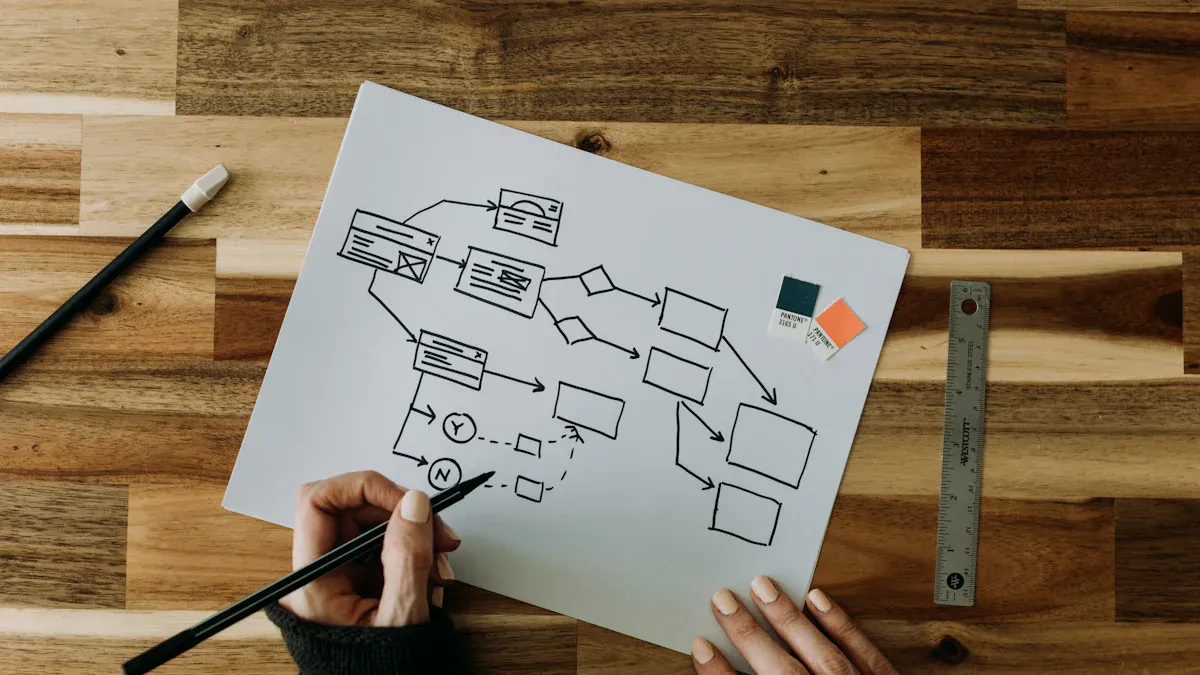

Tip: You can use process mapping and value stream mapping to visualize your workflow and spot areas for improvement.

Purpose

You use process improvement methodologies to achieve several important objectives. These frameworks help you identify and eliminate redundant steps that waste time and resources. You gain insight into the causes of inefficiencies, outdated systems, and miscommunication. By streamlining your processes, you enhance operations and automate tasks where possible.

You increase efficiency by removing unnecessary actions.

You improve quality by focusing on consistent results.

You boost customer value by delivering better products and services.

When you choose a methodology for process improvement, you set your organization on a path toward continuous growth. You create a culture that values learning and adaptation. You empower your team to solve problems and make decisions based on data. These benefits help you stay competitive and responsive in a changing business environment.

A table below shows some common methodologies and their main focus:

Methodology | Main Focus |

|---|---|

Six Sigma | Defect reduction, quality |

Lean | Waste elimination |

PDCA Cycle | Continuous improvement |

Kaizen | Small, ongoing changes |

TQM | Organization-wide quality |

Theory of Constraints | Bottleneck management |

You can select the right approach based on your goals and the challenges you face. Each methodology offers tools and techniques that guide you through the improvement process. You build a stronger organization by making thoughtful changes and measuring your results.

Methodology for Process Improvement

Six Sigma

Focus on Variation Reduction

You use Six Sigma when you want to reduce variation and improve quality in your processes. This methodology for process improvement relies on data and statistics to guide your decisions. You follow a structured approach called DMAIC, which stands for Define, Measure, Analyze, Improve, and Control. Each step helps you solve problems and make your process more reliable.

Define: You set clear goals and understand what your customers need.

Measure: You collect data to see how your process performs.

Analyze: You look for the root causes of defects or delays.

Improve: You create solutions and put them into action.

Control: You make sure the changes last and keep your process stable.

Six Sigma encourages you to focus on customer satisfaction and involve your team in every step. You use tools like process mapping and statistical analysis to find and fix problems. When you apply Six Sigma, you aim for fewer than 3.4 defects per million opportunities. This high standard means your process becomes predictable and consistent.

Many organizations have seen real results with Six Sigma. For example, a delivery service improved on-time deliveries by optimizing routes and using a standardized system. A pharmaceutical company reduced product defects by finding root causes and preventing mistakes. These changes led to happier customers and lower costs.

Tip: You can use Six Sigma to manage risks and make your process safer and more efficient.

Lean

Waste Elimination

Lean helps you remove waste and make your workflow smoother. This methodology for process improvement teaches you to focus only on activities that add value for your customers. You identify and eliminate anything that does not help deliver a better product or service.

Lean uses several tools to help you find and fix waste:

Bottleneck analysis helps you spot where work slows down.

Just-in-Time (JIT) production lets you make products only when needed.

Value stream mapping shows you every step in your process.

Error proofing prevents mistakes before they happen.

Root cause analysis helps you solve problems at their source.

You follow five main steps in Lean:

Identify value by understanding what your customers want.

Map the value stream to see where waste exists.

Create a flow so work moves smoothly.

Establish pull by producing only what is needed.

Seek perfection by always looking for ways to improve.

Lean highlights seven types of waste you should watch for:

Extra inventory

Overproduction

Over-processing

Unnecessary transportation

Excess motion

Waiting time

Defective products

When you use Lean, you make your process faster and more efficient. You also improve customer satisfaction by delivering what they need without delays or errors.

TQM

Quality Across Organization

Total Quality Management (TQM) helps you build quality into every part of your organization. This methodology for process improvement focuses on teamwork, leadership, and continuous learning. You create a culture where everyone works together to improve products and services.

TQM has several key elements:

Group | Elements |

|---|---|

Foundation | Ethics, Integrity, Trust |

Bricks | Training, Teamwork, Leadership |

Mortar | Communication |

Roof | Recognition |

You start with strong ethics and trust among your team. You train your employees and encourage teamwork. Leaders guide the process and make sure everyone understands the goals. Communication keeps everyone informed and motivated. Recognition rewards good work and inspires others to improve.

Organizations that use TQM see better performance and higher quality. Strong leadership and employee involvement make a big difference. You need to adapt TQM to fit your own business, since every organization is unique. Supplier quality management also plays a key role in success.

Note: TQM works best when you build a culture that values quality and supports continuous improvement.

PDCA Cycle

Plan, Do, Check, Act Steps

You can use the PDCA Cycle as a simple yet powerful methodology for process improvement. PDCA stands for Plan, Do, Check, Act. This cycle helps you solve problems and improve processes in a structured way. Many organizations rely on PDCA because it works in almost any industry.

Plan: You start by analyzing your current situation. Identify what you want to improve and set clear goals. Develop a plan with specific actions to reach those goals.

Do: Put your plan into action. Carry out the changes in a small, controlled way. This step lets you test your ideas without risking the whole process.

Check: Review the results. Compare what happened with your goals. Look for gaps or unexpected outcomes.

Act: If your plan worked, standardize the new process. If not, use what you learned to adjust your approach and start the cycle again.

You can apply PDCA in many real-world scenarios:

Manufacturing: Streamline production lines and reduce waste.

Service industries: Improve response times or customer experience.

Healthcare: Enhance patient flow or reduce errors.

Software development: Iterate on features and deployments.

Education: Refine teaching methods or administrative processes.

Organizations often use PDCA to drive continuous improvement. For example, in the automotive industry, teams have improved internal logistics and packaging quality by following the PDCA steps. Beverage companies have used PDCA to reduce product loss, while manufacturers have lowered defect rates and production delays.

Industry | Description | |

|---|---|---|

A structured model for continuous improvement methodology deployment and sustainment | Various | Provides a practical guide for running and monitoring PI projects to improve CI participation. |

Internal logistics process improvement using PDCA | Automotive | Utilized PDCA for quality improvement in sustainable packaging. |

Cleaner production and PDCA cycle | Beverage | Demonstrates PDCA application for reducing cans loss index. |

How PDCA Reduces Waste in Lean Manufacturing | Manufacturing | XYZ Manufacturing adopted PDCA to address high defect rates and production delays. |

Tip: You can repeat the PDCA cycle as many times as needed. Each cycle brings you closer to your goals and helps you build a culture of ongoing improvement.

Kaizen

Continuous Improvement

Kaizen means "change for the better." You use this approach to create a culture of continuous improvement in your organization. Kaizen encourages everyone to look for small, daily changes that add up to big results over time.

The philosophy behind Kaizen includes several key ideas:

Continuous Improvement: Always look for ways to improve processes, products, and services. Review your current practices, find areas to improve, and make changes for better results.

Standardization: Set clear and consistent work processes. Standardization makes it easier to spot problems and apply improvements.

Elimination of Waste: Identify and remove activities that do not add value. This step helps you streamline operations and boost efficiency.

Respect for People: Value your employees' ideas. Encourage everyone to share suggestions and take part in the improvement process.

When you use Kaizen, you see real benefits:

Higher employee morale as people feel motivated and engaged.

Stronger collaboration and trust within teams.

Improved customer focus, leading to greater satisfaction and loyalty.

Simplified quality control with fewer errors and more predictable results.

Reduced waste, making your operations leaner.

More scalable and sustainable growth through proactive problem-solving.

You can measure the success of Kaizen by tracking metrics like Overall Equipment Effectiveness (OEE), defect rates, and cost savings. These indicators show how well your improvements work and help you make better decisions.

Note: Kaizen works best when everyone in your organization takes part. Encourage open communication and celebrate small wins to keep momentum strong.

RAPID

Customized Approach

RAPID stands for Recommend, Agree, Perform, Input, and Decide. You use this methodology for process improvement when you need to clarify decision-making roles in complex situations. RAPID helps you assign clear responsibilities so your team can make faster, better decisions.

RAPID works well in organizations that face complex problems or high-stakes decisions. It also fits teams that need diverse input, strong collaboration, and clear accountability. If your organization wants to enhance transparency and communication, RAPID can help.

Here’s how RAPID breaks down:

Recommend: Someone suggests a course of action.

Agree: Key stakeholders must agree before moving forward.

Perform: The person or team carries out the decision.

Input: Others provide information or expertise to inform the decision.

Decide: One person or group makes the final call.

You can tailor RAPID to fit your needs. This flexibility makes it a valuable tool for organizations that want a customized approach to process improvement. RAPID ensures everyone knows their role, which reduces confusion and speeds up decision-making.

Tip: Use RAPID when you want to avoid bottlenecks and make sure every voice is heard in the decision process.

How It Works

Steps

You follow a clear sequence when you improve a process. Each step helps you move from identifying problems to making lasting changes. Here is a typical approach:

Identify improvement opportunities. You use process mapping, data analysis, and customer feedback to find areas that need attention.

Develop improvement strategies. You align these strategies with your organization’s goals.

Implement and monitor initiatives. You track progress and adjust your actions as needed.

Communicate the plan. You share details with all stakeholders to build support.

Provide training and support. You help staff understand new methods and encourage successful adoption.

Tip: You can repeat these steps for each process you want to improve. Consistency leads to better results over time.

Tools

You have access to many tools that make process improvement easier and more effective. Each tool serves a specific purpose and helps you reach your goals. The table below shows some common tools and how they contribute to success:

Tool/Methodology | Contribution to Success |

|---|---|

Six Sigma | Minimizes variations and defects, improving customer satisfaction through analytical processes. |

Standard Work | Establishes precise procedures to enhance safety and efficiency, reducing variations in product quality. |

Total Quality Management (TQM) | Focuses on ongoing improvement and customer satisfaction through data-driven decision-making. |

Plan Do Check Act (PDCA) Cycle | A dynamic approach for problem-solving and process improvement, ensuring continuous evaluation and adaptation. |

Business Process Management (BPM) | Analyzes and improves business processes, identifying bottlenecks and enhancing overall effectiveness. |

Continuous Improvement (Kaizen) | Promotes ongoing improvement to optimize value-generating activities and eliminate waste. |

5 Whys analysis | Identifies root causes of problems through iterative questioning, focusing on process errors. |

You select the right tool based on your specific challenge. For example, you might use Six Sigma to reduce defects or Kaizen to encourage small, daily improvements.

Roles

You need a strong team to make process improvement work. Each member brings unique skills and responsibilities. The table below outlines key roles and what they do:

Role/Responsibility | Description |

|---|---|

Diverse Expertise | Team members represent different knowledge and experience of the system. |

Executive Sponsor | Aligns the project with organizational strategy and provides resources. |

Day-to-Day Leader/Process Owner | Oversees project implementation and data collection, ensuring changes are effectively tested. |

Experience with Improvement Methods | At least one member guides the team with expertise in improvement methods. |

Technical/Clinical/Subject Matter Expert | Offers specialized knowledge relevant to the improvement project. |

Project Sponsor (System Leader) | Holds executive authority and acts as a liaison with senior management. |

You also focus on several responsibilities to ensure success:

Implement improvements based on monitoring and analysis.

Use the PDCA methodology for systematic management.

Ensure compliance with industry standards.

Recommend specialized training for team members.

Note: You build a stronger team by combining diverse skills and clear roles. This approach helps you achieve lasting improvements and meet your goals.

Benefits

Efficiency

You can achieve remarkable efficiency gains when you use process improvement methodologies. These approaches help you identify bottlenecks, remove unnecessary steps, and streamline your workflow. As a result, your team spends less time on repetitive tasks and more time on value-added activities.

Many organizations, including clients at systems and teams, have seen their productivity rise after adopting structured improvement methods. For example, when you map out your processes and eliminate waste, you can complete tasks faster and with fewer errors. This leads to smoother operations and better use of resources.

The table below shows typical efficiency improvements organizations experience:

Metric | Improvement Percentage |

|---|---|

Productivity | |

Defect Reduction | Up to 40% |

Operational Costs Reduction | 15-25% |

Resource Utilization Improvement | 30-40% |

Waste Reduction | 20-30% |

When you focus on efficiency, you empower your team to deliver results with less effort and time. This not only boosts morale but also frees up resources for innovation and growth.

Cost Savings

You can save significant costs by applying process improvement methodologies. These methods help you standardize work, reduce errors, and make better use of your resources. When you cut down on waste and rework, your organization spends less on corrections and overtime.

Clients at systems and teams have reported lower labor costs and reduced overhead after implementing Lean, Kaizen, and continuous improvement programs. For example, standardizing procedures leads to fewer mistakes, which means less time and money spent fixing problems. Lean principles in manufacturing can lower inventory costs and speed up production, giving you a competitive edge.

Here is a summary of how different methodologies contribute to cost savings:

Methodology | Cost-Saving Benefits |

|---|---|

Standardizing Work Procedures | Improved productivity and efficiency, fewer errors, increased consistency, and better client retention. |

Continuous Improvement Programs | Less rework, faster service delivery, improved resource use, and reduced waste. |

Lean Principles in Manufacturing | Higher product quality, less rework, lower warranty claims, reduced space and inventory costs, and improved cash flow. |

By focusing on cost savings, you can reinvest in your business, support new projects, and strengthen your financial position.

Quality

You improve quality when you use process improvement methodologies. These approaches help you set clear standards, monitor performance, and make regular adjustments. As a result, your products and services become more reliable and meet customer expectations.

Clients at systems and teams have seen measurable improvements in quality by adopting Six Sigma, Lean, TQM, and Kaizen. For example, Six Sigma in healthcare has reduced patient wait times and improved care. Lean methods have optimized patient flow and minimized delays. TQM has raised care standards and reduced errors. Kaizen encourages small, ongoing changes that add up to big quality gains.

The table below highlights how different methodologies lead to better quality:

Methodology | Industry | Measurable Improvement |

|---|---|---|

Six Sigma | Healthcare | Reduced patient wait times, enhanced care quality |

Lean | Healthcare | Optimized patient flow, minimized wait times |

TQM | Healthcare | Improved patient care standards, reduced errors |

Kaizen | Various | Regular minor adjustments leading to significant quality improvements |

When you focus on quality, you build trust with your customers and set your organization apart from competitors. High quality also reduces complaints and increases repeat business.

Customer Satisfaction

You improve customer satisfaction when you focus on process improvement methodologies. These approaches help you understand what your customers want and how they experience your services. You gather feedback regularly to find out where you can do better. You use tools like Net Promoter Score (NPS) analysis to measure customer loyalty and satisfaction. This score shows you how likely customers are to recommend your business to others. You also map the customer journey to see each step your customers take. This map helps you spot pain points and find ways to make their experience smoother.

When you listen to your customers and act on their feedback, you build trust and loyalty. You show that you care about their needs and want to deliver the best possible service.

You can use process improvement to make every interaction more positive. For example, you might shorten response times, reduce errors, or make your website easier to use. You can train your team to handle requests quickly and politely. These changes lead to higher satisfaction scores and more repeat business.

Here are some ways process improvement methodologies help you boost customer satisfaction:

You identify and fix problems that frustrate customers.

You create clear standards for service quality.

You respond faster to customer requests.

You personalize your services based on feedback.

You make it easier for customers to get help when they need it.

Methodology | Impact on Customer Satisfaction |

|---|---|

Lean | Faster service, fewer mistakes |

Six Sigma | Consistent quality, reliable outcomes |

Kaizen | Ongoing improvements, better experiences |

TQM | Organization-wide focus on customer needs |

Tip: You can use customer journey mapping to visualize each touchpoint and find new opportunities for improvement.

Choosing a Methodology

Assess Needs

You start by understanding what your organization needs before you select a process improvement methodology. You look at several criteria to make a smart choice. You check risk factors to see if the project might face challenges or need extra resources. You review project planning factors, such as how much time you have and how ready your team is for change. You measure process maturity by checking if your processes are well-documented and follow compliance rules. You also ask if your process fits automation, especially if it changes often or is complex. You identify the value by seeing how the process supports your strategic goals or brings financial benefits.

Criteria | Description |

|---|---|

Risk Factors | Assess potential risks involved in executing the project, including resource requirements and complexity. |

Project Planning Factors | Evaluate the timeline, capacity, and change management needs for the project. |

Process Maturity | Determine the maturity level of processes based on documentation and compliance measurements. |

Fit for Automation | Assess the suitability of robotic process automation based on process complexity and frequency of change. |

Value Identification | Analyze how the process aligns with strategic goals and its effectiveness or financial value. |

Tip: You can use this table to guide your team’s discussion and make sure you cover all important points.

Compare Options

You compare different methodologies to find the best fit for your business. You look at how each approach works and what results you can expect. Continuous improvement means you make small changes often. This lowers risk and helps your team stay engaged. Process improvement focuses on bigger changes. These changes can bring fast results but may need more planning and carry higher risks.

Continuous improvement uses ongoing small changes. You build a culture of engagement and lower risk.

Process improvement targets large changes. You get measurable results quickly but need structured project management.

Continuous improvement can boost employee satisfaction. Motorola saw a 25% increase in satisfaction scores.

Process improvement can save money fast. General Electric saved $2 billion with Six Sigma.

Continuous improvement may need more resources and can face resistance. Process improvement can cost more and create silos.

Note: You should weigh the pros and cons of each option. Think about your team’s readiness and the size of the change you want.

Key Factors

You consider several key factors when you choose a process improvement methodology. You match your goals to the right approach. For example, you pick Agile if you want speed. You check your organization’s culture. Kaizen works well if you want everyone involved. You evaluate how complex your processes are. Lean fits best for complex workflows. You review your resources and skills. Six Sigma needs strong data skills. You also look at timelines. Agile helps if you need quick results.

Key Factor | Explanation |

|---|---|

Match goals | Aligning business goals with the right methodology (e.g., Agile for speed). |

Check culture | Understanding organizational culture to choose a suitable approach (e.g., Kaizen for involvement). |

Evaluate complexity | Assessing process complexity to select appropriate methodologies (e.g., Lean for complex processes). |

Review resources | Considering available resources and skills (e.g., Six Sigma requires data skills). |

Consider timelines | Evaluating the time required for implementation (e.g., Agile for quick results). |

You make a better choice when you look at these factors together. You set your organization up for success by picking a methodology that fits your needs and strengths.

Implementation

Planning

You set the stage for successful process improvement by planning carefully. Good planning helps you avoid wasted effort and keeps your team focused. Start by making sure your improvement goals match your business objectives. When you align your changes with your company’s strategy, you keep everyone moving in the same direction.

Be specific about what you want to improve. Identify the exact process and set clear goals. This focus helps you measure progress and know when you succeed. Use data to guide your decisions. Data shows you where problems exist and helps you find the real causes. When you rely on facts, you avoid making changes based on guesswork.

Involve everyone who will be affected by the changes. Team members, managers, and even outside partners can offer valuable insights. When you include all stakeholders, you build trust and get better ideas. Open communication also helps you spot risks early.

Here are some best practices for planning a process improvement initiative:

Best Practice | Description |

|---|---|

Align with Your Business Goals | Make sure your changes support your company’s main objectives. |

Be Specific | Define the process and set clear, measurable goals. |

Be Data-Driven, Objective, & Critical | Use data to find problems and guide your decisions. |

Involve All Stakeholders | Engage everyone affected to gather insights and build support. |

Tip: Write down your goals and share them with your team. This step keeps everyone accountable and focused.

When you follow these steps, you create a strong foundation for your process improvement project. Careful planning helps you avoid surprises and keeps your team motivated.

Challenges

You face several challenges when you implement process improvement methodologies. Each obstacle can slow progress or reduce the impact of your efforts. Understanding these challenges helps you prepare and respond effectively.

Common Challenges You May Encounter:

Resistance to Change

Many employees feel uncertain when you introduce new methods. People often prefer familiar routines. You can overcome resistance by using strong change management strategies. Clear communication and showing the benefits of change help build trust.Lack of Alignment

Sometimes, departments or teams do not share the same goals. This lack of alignment can cause confusion and slow down improvement projects. You build alignment by encouraging teamwork and making sure everyone understands the purpose of the changes.Organizational Silos

Silos form when teams work separately and do not share information. These barriers prevent best practices from spreading. You break down silos by promoting collaboration and sharing knowledge across departments.Poor Communication

Misunderstandings happen when you do not have clear communication channels. Important details may get lost. You solve this by establishing open dialogue and making sure everyone knows how to share updates and feedback.Limited Resources

You may not have enough time, money, or staff to support improvement initiatives. This limitation can delay progress. You optimize resource use and seek support from leadership to secure what you need.Insufficient Training

Employees need new skills to use process improvement tools. Without proper training, mistakes can occur. You provide training programs to help your team learn and apply new methods confidently.Short-Term Focus

Some organizations only look for quick wins. This short-term focus can prevent lasting improvements. You balance immediate results with long-term goals to create sustainable change.

Tip: You can use regular check-ins and feedback sessions to spot challenges early and adjust your approach.

Challenge and Solution Table

Challenge | How You Overcome It |

|---|---|

Resistance to Change | Communicate clearly, show benefits, manage change |

Lack of Alignment | Build teamwork, clarify goals |

Organizational Silos | Promote collaboration, share best practices |

Poor Communication | Set up clear channels, encourage open dialogue |

Limited Resources | Optimize use, secure leadership support |

Insufficient Training | Offer training programs, support skill development |

Short-Term Focus | Balance quick wins with long-term improvement |

You improve your chances of success by addressing these challenges directly. You create a stronger foundation for process improvement when you plan for obstacles and respond with practical solutions. This approach helps your organization grow and adapt in a changing business environment.

You gain efficiency, cost savings, higher quality, and better customer satisfaction when you use process improvement methodologies. You choose the right approach to match your goals and build a stronger organization. You empower your team to solve problems and drive growth.

Boost productivity and reduce waste

Improve service quality and reliability

Increase customer loyalty

Ready to improve your processes? Contact systems and teams for expert guidance and support on your journey to operational excellence.

FAQ

What is the first step in process improvement?

You start by identifying which process needs improvement. Use data, feedback, or process mapping to spot problems. Clear goals help you focus your efforts and measure success.

How do you choose the right methodology?

You match your business goals and resources to the strengths of each methodology. Consider your team’s skills, the complexity of your process, and how quickly you need results.

Can small businesses use process improvement methodologies?

Yes, you can apply these methods in any size organization. Start with simple tools like process mapping or the PDCA cycle. Small changes often lead to big results.

How do you measure success in process improvement?

You track key performance indicators (KPIs) such as productivity, cost savings, or customer satisfaction. Regularly review your progress and adjust your approach as needed.

What if your team resists change?

You address resistance by communicating benefits clearly and involving your team early. Training and open discussions help build trust and support for new methods.

Do you need special software for process improvement?

You do not always need special software. Many tools, like flowcharts or checklists, work well on paper or with basic digital tools. For complex projects, software can help track progress.

How often should you review your processes?

You should review processes regularly, at least once a year or after major changes. Frequent reviews help you catch problems early and keep improving.

Tip: Involve your team in every review. Their insights often reveal hidden issues and new ideas.