Unlocking Efficiency with Six Sigma Process Mapping

Six Sigma Process Mapping transforms business management by making each process step visible and measurable. Teams use this knowledge to identify waste, streamline sales workflows, and support ongoing improvement. Organizations report up to 40% fewer defects and 30-40% better resource use after mapping processes.

Improvement Area | Percentage Improvement |

|---|---|

Productivity | 20-30% |

Defect Reduction | Up to 40% |

Operational Cost Reduction | 15-25% |

Resource Utilization Improvement | 30-40% |

Waste Reduction | 20-30% |

Mapping uncovers hidden waste, quantifies inefficiencies, and leads to measurable cost savings.

Benefit | Description |

|---|---|

Identifying Waste Sources | Discover both visible and invisible waste in operations, from scrap materials to excess inventory. |

Quantifying Waste | Measure the amount and types of waste, essential for setting achievable waste reduction goals. |

Optimizing Processes | Improve processes to minimize waste, enhancing efficiency and sustainability. |

Cost Savings | Reduce costs by using fewer raw materials and repurposing waste, turning rubbish into revenue. |

Environmental Impact | Lessen environmental footprint by diverting waste from landfills and cutting down on pollution. |

Key Takeaways

Six Sigma Process Mapping makes business processes visible and measurable, helping teams identify waste and inefficiencies.

Organizations can achieve up to 40% fewer defects and 30-40% better resource utilization through effective process mapping.

Visual diagrams highlight bottlenecks, allowing teams to quickly spot problems and streamline workflows.

Regular reviews of process maps support continuous improvement, helping organizations adapt to changes and enhance efficiency.

Involving all stakeholders in the mapping process ensures accuracy and helps capture every step of the workflow.

Keeping process maps simple and focused prevents confusion and enhances team collaboration.

Updating process maps regularly is crucial to reflect current operations and maintain their effectiveness.

Using tools like SIPOC diagrams and flowcharts can simplify complex processes and improve communication among team members.

Six Sigma Process Mapping and Efficiency

Visualizing Steps and Flows

Six Sigma Process Mapping gives teams a clear view of each step in a business process. Visual diagrams show how tasks move from one stage to the next. Teams see where work slows down or piles up. This visibility helps them spot problems quickly.

Visual diagrams highlight bottlenecks and inefficiencies.

Cycle time and cost analysis provide measurable indicators for performance.

Companies like Toyota and Motorola track defect rates and lead times to improve processes.

Teams use these maps to measure how long each step takes and how much each step costs. They compare results over time and find ways to improve. This approach makes every part of the process visible and measurable.

Reducing Waste and Bottlenecks

Six Sigma Process Mapping helps organizations find and remove waste. Teams look for steps that do not add value. They also search for bottlenecks that slow down progress. Process maps show where delays happen and where work gets stuck.

Benefit Description | Impact on Efficiency Gains |

|---|---|

Streamlining operational efficiency by clarifying each activity's role in workflows | Reduces costs and accelerates project completion, enhancing adaptability to change. |

Identifying idle time or delays in stages | Restructures workflows to maintain smooth operations. |

Eliminating unnecessary steps and simplifying workflows | Achieves faster results without sacrificing quality. |

Standardizing steps to minimize variations | Ensures consistent quality, crucial for long-term operational success. |

Focusing on high-impact activities that drive value | Frees up resources from low-priority tasks, enhancing overall productivity. |

Supporting effective information flow | Reduces miscommunication and ensures well-coordinated stages. |

Regularly reviewing process maps for adaptability | Allows organizations to adjust workflows as they scale or face new challenges. |

Ensuring functions support strategic objectives | Fosters unity and purpose within the organization. |

Streamlined processes resulting in faster response times | Enhances customer experience through higher quality and quicker service. |

Process maps help teams identify bottlenecks by showing stages with wait times or work accumulation. Teams use different strategies to address these issues.

Strategy Type | Strategy Description |

|---|---|

Short-Term | Resource Allocation: Reallocating resources to manage load at the bottleneck point. |

Process Adjustment: Modifying workflow or schedule to reduce load at the bottleneck. | |

Long-Term | Increase Capacity: Upgrading machinery or hiring additional staff to eliminate bottlenecks. |

Process Re-engineering: Redesigning the process to eliminate or distribute the load more evenly. | |

Technology Implementation: Using new technologies to automate or streamline the bottleneck stage. |

Teams use these strategies to keep work moving smoothly and reduce waste.

Supporting Continuous Improvement

Six Sigma Process Mapping supports ongoing improvement. Teams use process maps to review and refine workflows. They look for new ways to make processes faster and more reliable. Regular reviews help organizations adapt to changes and scale operations.

Mayo Clinic used process mapping to reduce patient wait times and cancellations.

Walmart improved supply chain management, leading to better inventory control and lower logistics costs.

Continuous improvement relies on clear process maps. Teams see what works and what needs change. They make small adjustments and measure results. This cycle leads to better efficiency and higher quality over time.

What is Six Sigma Process Mapping?

Definition and Purpose

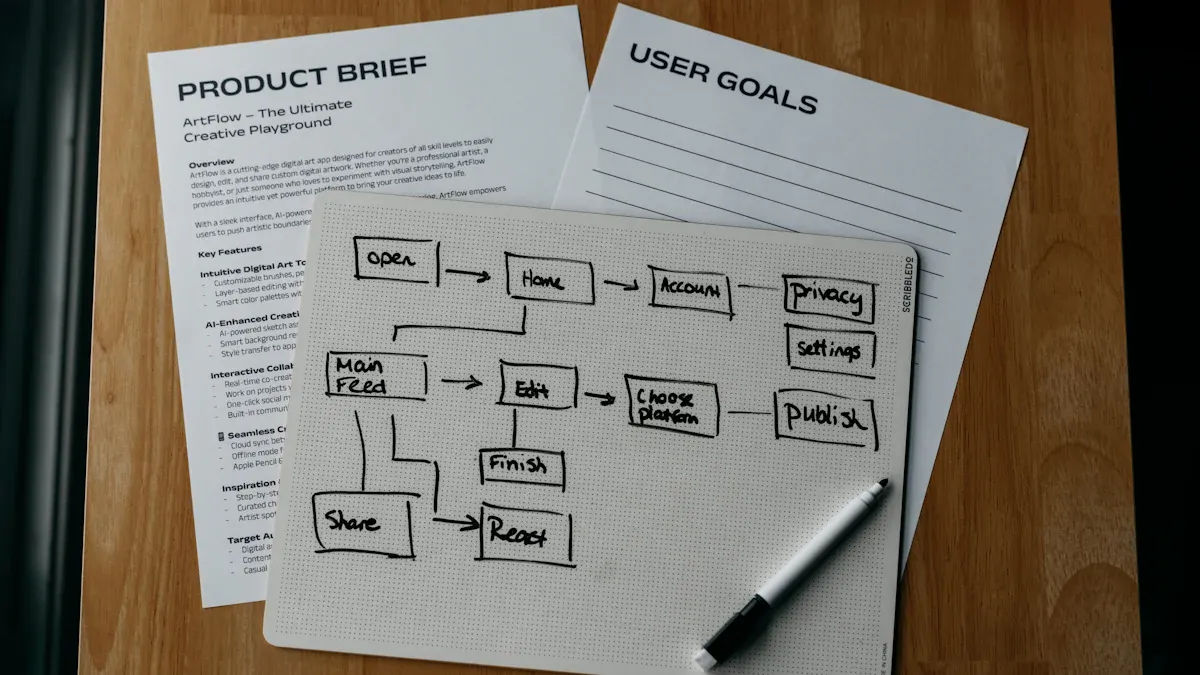

Six Sigma Process Mapping creates a visual representation of a business process. This map shows each step, decision point, and flow of work. Teams use these maps to understand how a process works from start to finish. The main purpose is to eliminate waste and reduce variation. When teams see the process clearly, they can spot steps that add no value or cause delays. A process map also helps everyone on the team share a common understanding. People outside the project team can use the map to learn about the process quickly.

Teams use process maps to identify complex steps that need simplification.

Visual maps allow easy comparison between current and improved processes.

Process maps help new team members or other departments understand workflows.

Key Principles

Six Sigma Process Mapping follows several key principles. First, it focuses on making processes visible. When people see the entire process, they can find problems faster. Second, it aims to simplify steps and remove unnecessary actions. Third, it encourages teams to measure each part of the process. This measurement helps track progress and set goals for improvement.

Note: The primary goal of Lean Six Sigma is to improve quality and efficiency by removing waste and reducing variation.

A good process map uses clear symbols and simple language. It should show the flow of work, decision points, and who is responsible for each step. Teams often update these maps as they improve the process.

Why It Matters

Six Sigma Process Mapping matters because it helps organizations see the entire process in one view. Visual maps turn abstract ideas into something people can understand quickly. Teams can detect waste faster and find steps that do not add value. This approach helps companies deliver on customer expectations by ensuring quality at every stage.

Visual maps help teams pinpoint areas that lower efficiency.

Updated process maps serve as training tools for new employees.

Organizations use these maps to store best practices and keep processes consistent.

When teams use process maps, they can respond to problems quickly. They also make it easier to train new staff and keep everyone on the same page. Over time, this leads to better quality, lower costs, and higher customer satisfaction.

Types of Process Maps in Six Sigma

SIPOC Diagram

Overview

A SIPOC diagram gives teams a high-level view of a process. The diagram includes five columns: Suppliers, Inputs, Process, Outputs, and Customers. Each column helps teams see who provides the inputs, which inputs matter most, the main steps in the process, the outputs created, and the customers who receive those outputs.

Teams use SIPOC diagrams to visualize the flow from start to finish.

The diagram highlights critical inputs and outputs.

It shows how each part connects, making it easier to spot gaps or overlaps.

A SIPOC diagram provides a macro and structured view. Teams quickly identify important flows and see how processes fit together.

When to Use

Teams often use SIPOC diagrams at the start of improvement projects. The diagram helps define process boundaries and validate problem statements. It is useful for training new employees, showing how different parts of the process link together.

SIPOC diagrams work best when teams need a broad overview.

They help clarify roles and responsibilities before diving into details.

The diagram supports communication between departments.

Flowchart

Elements

A flowchart breaks down a process into clear steps. Each step appears as a shape, such as a rectangle for actions or a diamond for decisions. Arrows show the direction of flow. Flowcharts can be simple or detailed, depending on the need.

Key Element | Role in Process Analysis |

|---|---|

SIPOC Diagram | Provides a high-level overview of the process and its components, useful at the start of improvement initiatives. |

High-Level Process Map | Illustrates basic steps for quick understanding, ideal for stakeholders needing an overview without details. |

Detailed Process Map | Captures all details necessary for identifying root causes of errors or waste, requiring input from process performers. |

Swimlane Diagram | Clarifies roles and responsibilities within the process, enhancing communication among team members. |

Flowcharts help teams see each step and decision point. They make it easier to analyze where errors or delays happen.

Applications

Teams use flowcharts to document current processes and design new ones. Flowcharts help identify unnecessary steps and improve workflow. They support Six Sigma Process Mapping by making each part of the process visible.

Flowcharts work well for both simple and complex processes.

They help teams communicate changes and train staff.

Flowcharts support root cause analysis by showing where problems start.

Value Stream Map

Mapping Value and Waste

A value stream map shows the entire workflow from start to finish. Teams use it to analyze efficiency and find waste. The map highlights steps that add value and those that do not. It helps teams focus on customer needs and improve overall workflow.

Type of Process Map | Purpose | Key Differences |

|---|---|---|

Process Map | Visual representation of workflow to understand day-to-day tasks. | Focuses on current process flow and specific steps involved in production. |

Value Stream Mapping | Analyzes entire workflow to improve efficiency and reduce waste. | Aims to eliminate waste (Muda) and enhance overall workflow, considering value addition for the customer. |

Teams use value stream maps to measure cycle times, wait times, and inventory levels. The map helps spot bottlenecks and areas for improvement.

Lean Six Sigma Use Cases

Value stream maps play a key role in Lean Six Sigma projects. Teams use them to reduce waste and improve efficiency. The map guides decisions about where to make changes. It helps teams prioritize actions that deliver the most value to customers.

Value stream maps support continuous improvement.

They help teams align process changes with business goals.

The map provides a clear path for reducing costs and increasing quality.

Swimlane Diagram

Roles and Responsibilities

A swimlane diagram organizes process steps into lanes that represent different roles, teams, or departments. Each lane shows who is responsible for specific tasks. This visual approach helps teams understand their duties and how their work connects with others. Swimlane diagrams use horizontal or vertical lanes to separate activities. Each lane belongs to a person or group. The diagram displays the flow of work from start to finish.

Teams use swimlane diagrams to clarify responsibilities. When each step appears in a lane, everyone sees who owns each part of the process. This method reduces confusion and helps prevent tasks from being missed. Managers use these diagrams to assign work and monitor progress. Employees see their roles and understand how their actions affect the outcome.

A swimlane diagram also supports training. New team members learn their responsibilities quickly by reviewing the diagram. The clear layout makes it easier to spot gaps in coverage or overlapping duties. Teams can adjust roles to improve efficiency.

Tip: Swimlane diagrams work best when teams update them regularly to reflect changes in roles or processes.

Cross-Functional Mapping

Swimlane diagrams play a key role in cross-functional Six Sigma projects. These projects often involve several departments or teams. The diagram shows how work moves between groups. Each lane represents a department, such as sales, production, or customer service. The diagram highlights handoffs and interactions.

Teams use swimlane diagrams to improve communication. When everyone sees the entire process, they understand how their work fits with others. This approach helps break down silos and encourages collaboration. Swimlane diagrams also help standardize processes across an organization.

Typical use cases for swimlane diagrams in cross-functional Six Sigma projects include:

Spotting redundant or unnecessary steps

Clarifying roles and responsibilities

Improving communication between departments

Standardizing processes across an organization

A swimlane diagram makes it easier to find bottlenecks. Teams see where work slows down or gets stuck between departments. They can address these issues by changing workflows or reallocating resources. The diagram also helps spot steps that do not add value. Teams remove or simplify these steps to improve efficiency.

Benefit | Description |

|---|---|

Clear Accountability | Each lane shows who is responsible for each step. |

Better Collaboration | Teams see how their work connects with others. |

Process Standardization | Diagrams help unify workflows across departments. |

Faster Problem Solving | Bottlenecks and delays become easy to identify. |

Swimlane diagrams give organizations a powerful tool for managing complex processes. Teams use them to clarify roles, improve communication, and streamline workflows. This approach supports Six Sigma goals by making processes visible and easier to improve.

Creating a Six Sigma Process Map

Define Scope and Goals

Teams begin Six Sigma Process Mapping by setting clear boundaries for the process. They decide where the process starts and where it ends. This step ensures everyone understands the purpose and expected outcomes. Defining the scope helps teams avoid confusion and keeps the project focused.

Tip: Teams should write down the goals before mapping begins. This practice keeps everyone aligned and makes it easier to measure success.

A recommended approach includes:

Define the scope by outlining the starting and ending points of the process.

Set specific goals for improvement, such as reducing defects or speeding up delivery.

When teams clarify the scope and goals, they create a strong foundation for the rest of the mapping process.

Identify and Sequence Steps

After setting the scope, teams list every step in the process. They gather information from people who perform the tasks daily. This step-by-step breakdown helps teams see the entire workflow and spot areas for improvement.

A best practice involves:

Assess the goals and outline the scope.

Identify each step by collecting details from team members.

Arrange the steps in the order they occur.

Teams often use sticky notes or digital tools to organize steps visually. Sequencing the steps helps teams understand how work flows from start to finish. This method makes it easier to find bottlenecks or unnecessary actions.

Note: Teams should involve people from different departments to ensure every step is captured accurately.

Document the Process

Once teams identify and sequence the steps, they create a visual diagram. Flowcharts are a popular choice for documenting processes. Each shape in the diagram represents a specific action or decision. Arrows show how tasks move from one step to the next.

A well-documented process map includes:

Clear labels for each step.

Decision points marked with diamonds.

Arrows that indicate the direction of workflow.

Teams use these diagrams to communicate with stakeholders and train new employees. A detailed process map makes it easier to spot errors and improve efficiency. Regular updates to the map help teams keep pace with changes in the business environment.

Teams should review the process map with all stakeholders before finalizing it. This step ensures accuracy and builds consensus.

Gather Feedback and Test

Teams improve Six Sigma process maps by gathering feedback from stakeholders. They invite people who work with the process daily to review the map. These individuals often spot missing steps or unclear instructions. Their input helps refine the map and ensures it matches real-world operations.

Testing the process map is essential. Teams run simulations or pilot the mapped workflow. They watch for errors, delays, or confusion during these trials. This approach reveals gaps and highlights areas for improvement.

Tip: Teams should encourage open discussion during feedback sessions. Diverse perspectives help identify inefficiencies and align the map with organizational goals.

A simple feedback and testing cycle includes:

Share the process map with all relevant team members.

Ask for comments on each step, especially where confusion or delays occur.

Conduct a trial run using the map, noting any issues.

Adjust the map based on feedback and test results.

Visual tools, such as flowcharts and swimlane diagrams, make it easier for everyone to understand the process. Using clear symbols ensures accessibility for all team members, regardless of their technical background.

Step | Action | Purpose |

|---|---|---|

Review | Stakeholders examine the process map | Spot missing or unclear steps |

Test | Simulate or pilot the workflow | Identify errors and bottlenecks |

Revise | Update the map based on findings | Improve accuracy and efficiency |

Teams treat process maps as living documents. They schedule regular reviews, such as quarterly or biannual, to keep maps current. This practice helps organizations adapt to changes in technology and goals.

Common Mistakes and Best Practices

Overcomplicating Maps

Many teams fall into the trap of making process maps too complex. They add unnecessary details, symbols, or steps that do not help solve the problem. This mistake can confuse team members and slow down progress. When a map becomes too complicated, people struggle to understand the workflow. They may miss important steps or overlook areas for improvement.

Overcomplicating the approach can lead to inefficiencies and misalignment in project goals. The key is to match the tool to the complexity of the problem—nothing more, nothing less.

Successful Six Sigma teams keep maps simple and focused. They include only the steps and information needed to reach the project goals. A clear map helps everyone see the process and work together to improve it.

Missing Stakeholders

Leaving out key stakeholders during process mapping can cause serious problems. Stakeholders bring valuable knowledge about how the process works. They help identify steps, spot errors, and suggest improvements. When teams do not include all stakeholders, they risk missing important details.

Increased need for rework

Risk of scope creep

Potential for project cancellation

Teams should invite people from every department involved in the process. They should ask for input from those who perform the tasks daily. This approach ensures the map reflects the real workflow and avoids costly mistakes. Including all stakeholders also builds support for changes and helps projects succeed.

Neglecting Updates

Process maps must stay current to remain useful. Many teams create a map and then forget to update it. Over time, processes change. New technology, staff, or regulations can affect how work gets done. An outdated map leads to confusion and errors.

Teams should review process maps regularly. The frequency depends on how stable the process is. Dynamic processes may need quarterly reviews. Stable processes could be reviewed annually. Teams must always update maps after significant changes.

Dynamic processes may need quarterly reviews.

Stable processes could be reviewed annually.

Always update after significant changes.

Regular updates keep process maps accurate and helpful. Teams can spot new problems and make improvements quickly. This habit supports continuous improvement and helps organizations adapt to change.

Linking Maps to Improvement Goals

Teams achieve the most value from Six Sigma process maps when they connect each map directly to measurable improvement goals. A process map should not exist in isolation. It must serve as a tool for tracking progress and driving results. Teams can use several strategies to ensure that process maps lead to real, measurable improvements:

Setting baseline metrics and goals

Teams begin by measuring current performance. They use these numbers as a starting point. Setting SMART goals—Specific, Measurable, Achievable, Relevant, and Time-bound—helps teams track success and stay focused.Creating real-time dashboards for tracking

Visual dashboards display key metrics. These dashboards allow teams to monitor progress as it happens. Quick access to data helps teams respond to problems before they grow.Using AI to reduce variation

Artificial intelligence tools can analyze process data. These tools find patterns and predict where problems might occur. Teams use this information to prevent errors and keep processes consistent.Embedding Lean Six Sigma in everyday work

Teams add quality checkpoints into daily routines. These checkpoints make quality measurement a habit, not an afterthought. Regular checks help teams catch issues early and maintain high standards.

Tip: Teams should review improvement goals often. Regular reviews keep everyone focused and allow for quick adjustments.

By following these strategies, teams ensure that process maps do more than document steps. They become living tools that guide improvement and deliver measurable results.

Maintaining and Updating Maps

A process map loses value if it does not reflect the current way of working. Teams must treat process maps as living documents. Best practices for maintaining and updating Six Sigma process maps include:

Regularly update process maps after any major change or Six Sigma project. This keeps the map accurate and useful.

Use digital platforms, such as Moxo, to connect maps with live workflows. Digital tools make updates faster and easier.

Ensure stakeholder validation. Teams should ask everyone involved in the process to review the map. This step confirms that the map matches reality.

Address potential blind spots. Teams should look for steps or details that might be missing. Filling these gaps prevents errors and inefficiencies.

Note: Teams that update process maps regularly adapt more quickly to changes in technology, staff, or business goals.

Maintaining accurate process maps supports continuous improvement. Teams can spot new problems, measure progress, and keep everyone aligned. An up-to-date map helps organizations respond to challenges and seize new opportunities.

Case Study: Six Sigma Process Mapping in Action

Background

A leading aerospace parts manufacturer faced growing pressure to deliver high-quality products faster. The company supplied critical components to major aircraft builders. Their clients demanded shorter lead times and consistent quality. The manufacturer relied on complex machining processes that involved multiple teams and advanced equipment. Each team handled a different stage, from raw material preparation to final inspection. The company wanted to improve efficiency across these systems and meet client expectations for reliability and speed.

Challenges

The organization encountered several obstacles before starting their improvement journey. The following table outlines the main challenges:

Challenge | Description |

|---|---|

Projects often failed without genuine leadership buy-in, which required more than just executive signatures. | |

Flawed Project Selection | Teams sometimes chose projects based on intuition or personal preference, leading to poor results or wasted effort. |

Difficulty with Data Collection & Analysis | The company struggled to gather clean, actionable data, which is essential for a data-driven approach. |

These challenges slowed progress and made it difficult for teams to identify the root causes of inefficiency. Without strong leadership support, projects lost momentum. Poor project selection led to wasted resources. Data issues prevented teams from making informed decisions.

Solutions

The manufacturer decided to implement Six Sigma Process Mapping to address these issues. Teams began by mapping every step of the machining workflow. They involved operators, engineers, and quality specialists to ensure accuracy. The process maps revealed hidden delays and unnecessary handoffs between teams. By visualizing the entire workflow, teams identified bottlenecks and steps that did not add value.

Teams used process maps to clarify roles and responsibilities.

They standardized procedures across departments.

The company introduced regular reviews to keep maps up to date.

Teams focused on collecting accurate data at each stage.

This approach helped systems and teams work together more effectively. Clients benefited from faster turnaround times and improved product consistency. The company achieved a 46% reduction in machining cycle time and an 80% decrease in process variation. These results led to higher productivity and greater customer satisfaction.

Note: Involving all stakeholders in mapping and review sessions ensured that improvements matched real-world needs.

Results

The aerospace parts manufacturer saw significant improvements after using Six Sigma process mapping. The teams worked together to make each step in the process clear and measurable. This approach helped them find and remove waste, reduce errors, and improve quality.

The company tracked several key metrics before and after the changes. The table below shows the results:

Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

5.5% | 3.08% | Reduced by 2.42% | |

Number of Rejected Pieces | 153 | 68 | Reduced by 85 pieces |

Cost Savings per Month | N/A | Rs. 15,249 | N/A |

Sigma Level | 3.9 | 4.45 | Improved by 0.55 |

The rejection rate dropped from 5.5% to 3.08%. This change meant fewer parts failed quality checks. The number of rejected pieces fell from 153 to 68. Teams saved time and resources by producing more parts that met standards on the first try.

The company also saw cost savings each month. After the improvements, they saved Rs. 15,249 monthly. These savings came from using materials more efficiently and reducing the need for rework. The process became more reliable, which helped the company meet customer demands faster.

The Sigma level increased from 3.9 to 4.45. This metric shows how well the process performed with fewer defects. A higher Sigma level means the process produced higher quality parts with less variation. The teams used this data to track progress and set new goals for future improvements.

Six Sigma process mapping helped the manufacturer achieve these results by making every step visible and measurable. Teams could see where problems started and fix them quickly. The company built a culture of continuous improvement. Employees felt more confident in their roles because they understood the process better.

Regular reviews and updates to the process map kept the improvements on track. The company continued to monitor results and look for new ways to get better.

The case study shows that clear process mapping leads to real, measurable gains. The manufacturer improved quality, reduced waste, and saved money. These results demonstrate the power of Six Sigma process mapping for any organization that wants to boost efficiency and deliver better products.

Six Sigma process mapping helps teams boost efficiency by making every step clear and measurable. Teams who follow best practices and avoid common mistakes see real improvements in quality and cost savings. Process maps guide teams to spot waste and fix problems quickly.

Those who want to learn more about achieving similar results with their systems and teams can reach out for further information.

FAQ

What is the main goal of Six Sigma process mapping?

Six Sigma process mapping helps teams see each step in a workflow. The main goal is to find waste and improve efficiency. Teams use maps to make processes clearer and easier to manage.

How often should teams update process maps?

Teams should review process maps after major changes. Many organizations schedule updates every quarter or year. Regular updates keep maps accurate and useful.

Which process map works best for cross-functional teams?

Swimlane diagrams work well for cross-functional teams. These diagrams show roles and responsibilities. Teams use them to improve communication and clarify tasks.

Can process mapping help reduce costs?

Process mapping helps teams find waste and unnecessary steps. By removing these, organizations save money. Many companies report lower operational costs after mapping their processes.

What tools do teams use to create process maps?

Teams use digital tools like Lucidchart, Microsoft Visio, or Miro. These platforms offer templates and symbols for easy mapping. Some teams also use sticky notes for quick drafts.

Why is stakeholder involvement important in process mapping?

Stakeholders know the details of each step. Their input helps teams create accurate maps. Involving stakeholders ensures the process map matches real operations.

How does process mapping support continuous improvement?

Teams use process maps to track changes and measure results. Regular reviews help teams find new ways to improve. This cycle supports ongoing efficiency and quality gains.