What is Six Sigma Methodology Tools and Techniques You Should Know

Six Sigma Methodology uses a disciplined, data-driven process to improve quality and reduce defects in organizations. Statistically, it aims for just 3.4 defects per million opportunities, setting a high standard for process performance. Teams apply structured frameworks like DMAIC and DMADV, relying on statistical tools to minimize process variability and meet customer needs. Companies such as Johnson & Johnson and Texas Instruments have reported significant cost savings and improved Sales and Business Management after adopting this approach. Knowledge of Six Sigma helps systems and teams achieve operational excellence.

Key Takeaways

Six Sigma uses data and structured methods to reduce defects and improve quality in processes.

The DMAIC framework helps fix existing processes, while DMADV guides the design of new ones.

Key tools like SIPOC diagrams, control charts, and fishbone diagrams help teams analyze and improve workflows.

Certification levels from White Belt to Master Black Belt build skills and leadership in Six Sigma projects.

Strong leadership support and clear project goals are essential for successful Six Sigma implementation.

Combining Lean and Six Sigma removes waste and reduces defects, boosting efficiency and customer satisfaction.

Teams that focus on customer needs and use data-driven decisions achieve better, lasting results.

Overcoming challenges like resistance to change requires communication, training, and pilot projects.

Why Six Sigma Matters

Benefits

Six Sigma offers many advantages for organizations that want to improve quality and efficiency. Systems and teams that use Six Sigma see fewer defects and more reliable processes. The approach combines Lean’s focus on removing waste with Six Sigma’s goal of reducing variation. This combination leads to better products and services.

Some of the most significant benefits include:

Cost Reduction: Six Sigma helps companies cut waste and streamline operations. This leads to lower production and operational costs.

Enhanced Customer Satisfaction: By improving quality and reducing errors, organizations deliver better experiences to their clients. For example, Amazon used DMAIC to reduce errors and saw customer satisfaction scores rise by 5% from 2021 to 2024.

Increased Employee Engagement: Six Sigma involves employees in problem-solving. Teams become more invested in their work, which boosts morale and sparks innovation.

Operational Excellence: The method encourages continuous improvement and data-driven decisions. Many industries, such as healthcare, IT, retail, and finance, use Six Sigma to achieve high standards.

Long-Term Value: While some organizations face resistance to change and training costs, the long-term gains outweigh these challenges. Leadership support and certified professionals help ensure success.

Six Sigma fosters a culture of continuous improvement, making it a valuable tool for any organization aiming for excellence.

Benefit Category | Description | Real-World Example / Impact |

|---|---|---|

Cost Reduction | Eliminates waste and streamlines operations, reducing production and operational expenses. | Leads to higher profit margins and stronger competitive positioning. |

Enhanced Customer Satisfaction | Improves product quality and reduces defects, resulting in superior customer experience. | Amazon uses DMAIC to reduce errors, improving customer satisfaction scores by 5% from 2021 to 2024. |

Increased Employee Engagement | Involves employees in problem-solving and continuous improvement, boosting morale and innovation. | Employees become more invested, fostering a productive and innovative work environment. |

Operational Excellence | Drives continuous process improvement and data-driven decision-making across industries. | Adopted widely in manufacturing, healthcare, IT, retail, finance, and public agencies. |

Challenges and Mitigation | Resistance to change and upfront training costs exist but are outweighed by long-term benefits. | Leadership commitment and certified professionals (Black Belts) are key to successful implementation. |

Industry Use

Six Sigma has a strong presence in many industries. Manufacturing companies often lead the way, but service sectors also benefit. For example, a Canadian manufacturer saved about $10 million in energy costs over eight years by using Lean Six Sigma and new technologies. The company increased production capacity and reduced downtime by shifting work to off-peak hours and improving machine maintenance.

Many well-known companies use Six Sigma to improve their systems and teams:

Amazon

Atos

Autoliv

BAE Systems

Bank of America

Becton Dickinson

Bechtel

Xerox

These organizations have seen gains in quality, efficiency, and customer satisfaction. Six Sigma helps both manufacturing and service industries meet high standards and deliver better results to clients.

Business Impact

Six Sigma drives real business results. Motorola, for example, reported $17 billion in savings after adopting Six Sigma. The method reduces process variation and defects, leading to better products and services. Systems and teams that use Six Sigma identify root causes of problems and fix them, which improves efficiency and profitability.

Success depends on strong leadership and training at all levels. When organizations commit to Six Sigma, they see lasting improvements in performance. Teams become more skilled at solving problems, and clients receive higher-quality outcomes. For those interested in learning more or improving their own systems, reaching out for guidance or training can help unlock these benefits.

Six Sigma Methodology

Core Principles

Six Sigma Methodology stands on a foundation of clear principles that guide systems and teams toward better performance. These principles help organizations reduce defects, improve efficiency, and meet customer needs. Research and industry experience confirm the effectiveness of these guiding ideas.

Intense Customer Focus: Teams listen to the Voice of the Customer (VOC) to ensure every improvement meets real needs.

Data-Driven Decisions: Systems rely on facts and statistical analysis, not opinions, to solve problems.

Strong Process Orientation: Teams view problems as process issues, not individual mistakes, and work to refine those processes.

Proactive Management: Practitioners anticipate problems and prevent them through careful risk assessment and trend analysis.

Collaboration Across Boundaries: Cross-functional teamwork breaks down silos, allowing systems to improve together.

Pursuit of Perfection: Teams aim for near-perfect quality, learning from failures and striving for continuous improvement.

Six Sigma Methodology integrates these principles into every project, ensuring that systems and teams achieve measurable results. Studies show that organizations using these principles see better outcomes in manufacturing, healthcare, and service industries.

Customer Focus

Customer focus sits at the heart of Six Sigma Methodology. Teams gather feedback, research preferences, and align processes to deliver value. This approach leads to higher productivity, better retention, and a strong competitive edge. By integrating the Voice of the Customer into every step, systems ensure that improvements match what clients want.

A study by the International Six Sigma Institute found that companies using customer feedback in their projects reduced defects by 25% and increased customer satisfaction by 15%. Real-world examples show that organizations like GE and Ford improved product reliability and reduced warranty claims by focusing on customer needs. In healthcare and retail, systems that addressed complaints and process gaps saw higher satisfaction scores.

Teams that prioritize customer focus build trust and loyalty. Clients notice when systems deliver consistent quality and respond to their needs.

Data-Driven Approach

Six Sigma Methodology depends on data and statistical analysis to guide decisions. Teams collect relevant data, analyze trends, and identify root causes. This process removes guesswork and leads to more accurate solutions.

Data Type | Description | Common Tools | Impact on Accuracy |

|---|---|---|---|

Measured on a scale (cycle time, satisfaction) | Regression, ANOVA | Reveals trends and variations for better decisions | |

Discrete Data | Counted or categorized (defect counts, complaints) | Pareto, Control Charts | Helps prioritize issues and monitor process stability |

Teams use tools like control charts, Pareto charts, and regression analysis to find patterns and solve problems. In manufacturing, systems have reduced defects by tracking root causes. In healthcare, data analysis improved patient satisfaction. Financial services streamlined loan processing by analyzing inefficiencies.

Modern Six Sigma Methodology adapts to digital transformation. Teams use real-time sensor data, AI, and cloud platforms to predict defects and speed up improvements. Organizations that use digital tools report faster project completion and higher customer satisfaction. Practitioners now need skills in data science and digital analytics to keep up with these trends.

Data-driven decision-making ensures that systems and teams act on facts, not assumptions. This leads to faster, more reliable improvements and better outcomes for clients.

DMAIC & DMADV

Six Sigma Methodology uses two main project frameworks: DMAIC and DMADV. Both help systems and teams improve quality, but each fits different types of projects.

DMAIC Steps

DMAIC stands for Define, Measure, Analyze, Improve, and Control. Systems and teams use this method to fix and optimize existing processes.

Define

Teams identify the problem, set clear goals, and outline the project scope. They use tools like project charters and SIPOC diagrams to understand the process and what success looks like.

Measure

Teams collect data to see how the current process performs. They measure defects, errors, and set a baseline. This step ensures decisions rely on facts, not guesses.

Analyze

Teams use statistical tools, such as control charts and fishbone diagrams, to find the root causes of problems. They focus on solving the real issues, not just symptoms.

Improve

Teams develop and test solutions on a small scale. They use methods like brainstorming and FMEA to make sure changes lead to real improvements before rolling them out fully.

Control

Teams set up monitoring plans, update procedures, and train staff. They use dashboards and audits to make sure improvements last and prevent old problems from returning.

DMAIC’s structured, data-driven approach helps systems and teams reduce ambiguity and achieve lasting results.

DMADV/DFSS Steps

DMADV stands for Define, Measure, Analyze, Design, and Verify. Systems and teams use this method when creating new processes or products.

Define

Teams set project goals, scope, and customer requirements. They create a project charter and plan resources.

Measure

Teams gather customer data and translate needs into measurable design requirements. They identify risks early.

Analyze

Teams develop and compare different design options. They use tools like benchmarking to select the best fit for customer needs.

Design

Teams build detailed plans for the chosen solution. They use simulations and analysis to ensure the design works in real-world conditions.

Verify

Teams test prototypes or pilot builds. They check if the design meets customer and performance requirements before full launch.

DMADV helps systems and teams get new processes right the first time, reducing defects and boosting customer satisfaction.

When to Use Each

Choosing between DMAIC and DMADV depends on the project’s goal:

Feature | DMAIC | DMADV |

|---|---|---|

Improve existing processes | Design new processes or products | |

Focus | Correct current problems | Prevent future problems |

Approach | Reactive | Proactive |

Data Focus | Current process data | Customer needs and specifications |

Outcome | Stable, improved process | Validated new design |

Use DMAIC for existing processes that need improvement and root cause analysis.

Use DMADV for new products, services, or major redesigns where customer-driven design is key.

Systems and teams may use both: DMADV for initial design, DMAIC for ongoing optimization.

If systems and teams want to learn more about which approach fits their needs, they can reach out for guidance.

Six Sigma Tools

Six Sigma Methodology relies on a variety of tools to help systems and teams visualize, analyze, and improve processes. These tools fall into three main groups: process mapping, data analysis, and root cause analysis. Each group supports a different stage of improvement projects and helps teams achieve measurable results.

Process Mapping

Process mapping tools give teams a clear picture of how work flows through a system. These visual tools help identify bottlenecks, waste, and inefficiencies. By mapping out each step, teams can see where problems occur and where improvements will have the most impact.

SIPOC

A SIPOC diagram stands for Suppliers, Inputs, Process, Outputs, and Customers. Teams use SIPOC diagrams at the start of a project to define the boundaries and key elements of a process. This tool helps everyone understand who provides inputs, what those inputs are, how the process works, what outputs are produced, and who receives them. SIPOC diagrams keep projects focused and ensure that improvements align with customer needs.

Flowchart

Flowcharts use symbols and arrows to show the sequence of steps in a process. Teams use flowcharts to break down complex workflows into simple, easy-to-follow diagrams. This makes it easier to spot unnecessary steps, delays, or points where errors can occur. Flowcharts also help new team members understand how a process works.

Value Stream Map

Value stream mapping takes process mapping a step further by showing both the flow of materials and information. Teams use value stream maps to identify every step in a process, from start to finish. This tool highlights where value is added and where waste occurs. For example, Toyota’s Production System uses value stream mapping to smooth workflows and increase throughput. Hospitals have reduced patient wait times by 15% by streamlining discharge processes with value stream maps. In manufacturing, teams have improved throughput by 30% and reduced work-in-process inventory by 20% after identifying bottlenecks. These results show how process mapping tools help systems and teams achieve measurable operational gains.

Process mapping tools such as SIPOC diagrams, flowcharts, and value stream maps provide structured visualizations of workflows. They help teams clarify roles, highlight inefficiencies, and support continuous improvement.

Data Analysis

Data analysis tools help teams collect, organize, and interpret data. These tools reveal patterns, trends, and problem areas that might not be obvious. By using data analysis, systems and teams can make decisions based on facts rather than guesses.

Check Sheet

A check sheet is a simple form for collecting data in real time at the location where the data is generated. Teams use check sheets to track the frequency of specific events, such as defects or errors. This tool helps teams gather reliable data quickly and spot trends over time.

Histogram

A histogram displays data in bars to show the distribution of values. Teams use histograms to see how often different results occur. This helps them understand the spread and center of the data, and spot any unusual patterns. For example, a team might use a histogram to see if most defects happen during a certain shift or at a specific machine.

Pareto Chart

A Pareto chart combines bars and a line graph to show which factors contribute most to a problem. Teams use Pareto charts to focus on the “vital few” causes that create the majority of defects. By addressing these key issues first, teams can achieve the biggest improvements with the least effort.

Scatter Diagram

A scatter diagram plots pairs of data points to show if there is a relationship between two variables. Teams use scatter diagrams to see if changes in one factor might cause changes in another. For example, a team might look for a link between machine speed and defect rates.

Control Chart

A control chart tracks process data over time and compares it to control limits. Teams use control charts to monitor process stability and spot unusual variation. If a process goes out of control, the chart signals the team to investigate and take corrective action. This helps maintain consistent quality.

Histograms, Pareto charts, and control charts help teams visualize data, prioritize problems, and monitor process stability. These tools support data-driven decision-making and continuous improvement, which are essential for reducing defects in Six Sigma projects.

Root Cause

Root cause analysis tools help teams dig deeper to find the real reasons behind problems. Instead of treating symptoms, these tools guide teams to the source of defects or inefficiencies.

Fishbone Diagram

The fishbone diagram, also called the Ishikawa or cause-and-effect diagram, helps teams organize possible causes of a problem into categories such as manpower, machinery, materials, and methods. By brainstorming and mapping out these causes, teams can see all possible factors and focus their investigation.

5 Whys

The 5 Whys technique involves asking “why?” multiple times—usually five—to drill down to the root cause of a problem. Each answer forms the basis for the next question. This simple but powerful tool helps teams move past surface-level issues and uncover the underlying cause.

Root cause analysis tools like the fishbone diagram and 5 Whys enable systems and teams to move beyond symptoms and target corrective actions where they will have the greatest impact. These tools have improved quality, reliability, and efficiency in many Six Sigma Methodology projects.

If systems and teams want to learn more about using these tools or need guidance on selecting the right approach, they can reach out for expert support.

Statistical Tools

Statistical tools help systems and teams make decisions based on data. These tools allow teams to test ideas, find relationships, and improve processes with confidence. In Six Sigma projects, three main statistical tools stand out: hypothesis testing, regression analysis, and design of experiments (DOE).

Hypothesis Test

A hypothesis test checks if a change in a process leads to real improvement or if the difference happened by chance. Teams use this tool during the Measure and Analyze phases. For example, a team might use a two-sample t-test to compare product accuracy before and after equipment maintenance. If the test shows a p-value less than 0.05, the improvement is statistically significant. This means the change made a real difference, not just a random one.

Hypothesis testing gives teams confidence that their solutions work. It helps avoid costly mistakes and supports data-driven decisions.

Regression

Regression analysis finds connections between different factors in a process. Teams use regression to predict how changes in one variable affect another. For example, a team might use multiple regression to see how cutting speed and feed rate affect product quality. The analysis might show that both cutting speed and feed rate matter, but coolant temperature does not. This helps teams focus on what really drives results.

A table can show how regression helps teams:

Variable | Significant? | Impact on Quality |

|---|---|---|

Cutting Speed | Yes | High |

Feed Rate | Yes | Medium |

Coolant Temperature | No | Low |

Teams use regression to set the best process conditions and predict future outcomes.

DOE (Design of Experiments)

Design of Experiments (DOE) is a powerful tool for testing several factors at once. Teams plan experiments where they change inputs in a controlled way and measure the results. DOE helps find which factors matter most and what settings give the best results. For example, a team might use a full factorial design to test different speeds and feed rates. They can then use Response Surface Methodology (RSM) to fine-tune the process.

DOE leads to:

Reduced process variability

Improved efficiency

Consistent achievement of goals

Teams that use DOE often see cost savings and better quality. After improvements, process capability indices like Cp and Cpk can rise, showing more stable and predictable processes.

Statistical tools like hypothesis testing, regression, and DOE help systems and teams make smart choices, optimize processes, and achieve measurable improvements.

Project Tools

Project tools help systems and teams plan, track, and complete Six Sigma projects successfully. These tools keep everyone organized, make sure resources are used well, and help teams reach their goals on time.

FMEA

Failure Modes and Effects Analysis (FMEA) helps teams find possible problems before they happen. Teams list all the ways a process could fail, the effects of each failure, and how likely each one is. They then rank the risks and focus on the most serious ones. FMEA helps teams prevent issues, reduce waste, and improve safety.

RACI

A RACI matrix shows who is Responsible, Accountable, Consulted, and Informed for each task in a project. This tool makes roles clear and avoids confusion. For example, a team might use a RACI chart to show that one person is responsible for collecting data, another is accountable for the results, and others are consulted or informed. This keeps projects running smoothly.

Gantt Chart

A Gantt chart is a timeline that shows when each part of a project will happen. Teams use Gantt charts to plan tasks, set deadlines, and track progress. Scheduling tools like Microsoft Project help teams update Gantt charts as work moves forward. This makes it easy to spot delays and adjust plans.

Project tools like FMEA, RACI, and Gantt charts help systems and teams manage resources, track progress, and deliver results. Teams use word processors for documentation, spreadsheets for tracking costs, and scheduling tools for planning. These tools make projects more predictable and successful.

If systems and teams want to learn more about using these tools or need help choosing the right ones, they can reach out for expert support.

Certification & Roles

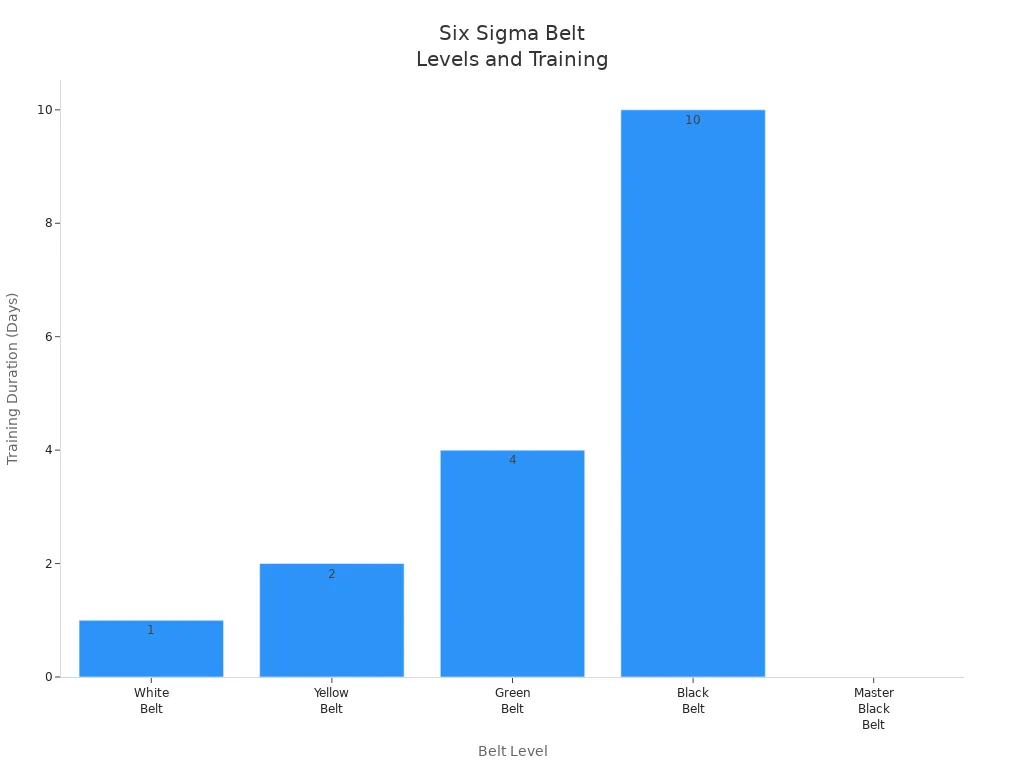

Six Sigma certification follows a clear hierarchy. Each belt level represents a different set of skills, responsibilities, and leadership roles within systems and teams. As individuals progress, they gain deeper knowledge and take on more complex projects. This structure helps organizations build strong improvement teams and ensures that every member contributes effectively.

Belt Level | Knowledge Level | Typical Role | Average Salary | |

|---|---|---|---|---|

White Belt | Basic Awareness | Team Member | 1 Day | $50,000 - $60,000 |

Yellow Belt | Foundational | Project Team Member | 2 Days | $60,000 - $70,000 |

Green Belt | Intermediate | Project Leader | 4 Days | $70,000 - $90,000 |

Black Belt | Advanced | Project Manager | 10 Days | $90,000 - $120,000 |

Master Black Belt | Expert | Strategic Leader | Varies | $120,000 - $170,000 |

This table shows how Six Sigma belts move from basic awareness to expert leadership. Training time and salary increase with each level, reflecting greater responsibility and expertise.

Yellow Belt

Yellow Belts hold foundational knowledge of Six Sigma tools and techniques. They support Green Belt and Black Belt projects by participating in teams and contributing to problem-solving. Yellow Belts help collect data, create process maps, and assist with root cause analysis. They do not lead projects but play a key role in supporting improvement efforts.

Possesses basic knowledge of Six Sigma tools

Supports higher-level projects

Participates in team-based problem-solving

Systems and teams rely on Yellow Belts to ensure that improvement projects run smoothly. Their involvement helps projects stay organized and focused.

Green Belt

Green Belts have intermediate skills and often lead smaller projects within their departments. They use Six Sigma methods to analyze data, identify process issues, and implement solutions. Green Belts guide Yellow Belts and work closely with Black Belts for larger initiatives.

Green Belts typically:

Lead project teams for process improvement

Analyze data using Six Sigma tools

Train and mentor Yellow Belts

Report progress to management

Systems and teams benefit from Green Belts by gaining leaders who can drive change and deliver measurable results.

Black Belt

Black Belts hold advanced knowledge and manage complex projects that impact multiple departments. They use statistical analysis, lead cross-functional teams, and ensure that projects align with business goals. Black Belts also coach Green and Yellow Belts, sharing expertise and building team capability.

Black Belts:

Manage large-scale improvement projects

Use advanced statistical tools

Mentor and train other belts

Align projects with organizational strategy

As systems and teams develop more Black Belts, they see greater improvements in quality and efficiency. Clients benefit from projects that deliver lasting value.

If systems and teams want to learn more about building strong Six Sigma teams or advancing their own skills, they can reach out for guidance and support.

Master Black Belt

The Master Black Belt represents the highest level of Six Sigma expertise. Individuals at this level guide systems and teams across the organization. They do not just lead projects; they shape the overall strategy for quality improvement. Master Black Belts train and mentor Black Belts and Green Belts. They analyze complex data, solve advanced problems, and help set company-wide standards.

A Master Black Belt often works with leadership to align Six Sigma goals with business objectives. This role requires deep knowledge of statistics, project management, and change leadership. Master Black Belts also review project results and ensure that teams follow best practices. They play a key part in building a culture of continuous improvement.

Master Black Belts help systems and teams reach new levels of performance. Their guidance leads to fewer defects, better efficiency, and higher customer satisfaction.

Champion

Champions hold leadership positions within organizations. They support Six Sigma by providing resources, removing obstacles, and setting priorities. Champions work closely with Master Black Belts to make sure projects align with business goals. They do not manage day-to-day tasks but focus on strategy and results.

Champions help select the right projects and ensure teams have what they need to succeed. They also communicate the value of Six Sigma to other leaders and stakeholders. By doing so, Champions create an environment where systems and teams can thrive.

A Champion’s support often makes the difference between a successful project and one that stalls. Their leadership helps clients see real improvements in quality and business performance.

Getting Certified

Earning a Six Sigma certification shows a strong commitment to quality and process improvement. The certification process involves training, hands-on project work, and passing an exam. Each belt level has its own requirements and focus areas.

Belt Level | Description & Process |

|---|---|

White Belt | Basic awareness of Six Sigma concepts; no formal training or certification required. |

Yellow Belt | One- or two-day training; deeper understanding than White Belt; able to assist on projects and guide smaller ones. |

Green Belt | Complete course covering Six Sigma methods (e.g., DMAIC); prepares for active roles in process improvement. |

Black Belt | Advanced training including LEAN principles; leads complex projects and teams; requires hands-on project experience. |

Master Black Belt | Expert level; oversees strategy and coordinates large projects across the organization. |

Champion | Upper management role; leads LEAN strategy and deployment; comprehensive understanding of Six Sigma processes. |

Most certification programs require candidates to complete training and pass a written exam. Some programs allow individuals to skip certain belt levels if they show enough knowledge and experience. The duration of training varies. For example, Black Belt training often takes several months.

Recognized certifying bodies include the American Society for Quality (ASQ) and the International Association for Six Sigma Certification (IASSC). These organizations offer exams in different formats, such as open-book or closed-book tests.

Students who prepare well for the certification exam have a high chance of success. For example, students at Bemidji State University achieved a 96% pass rate on the Lean Six Sigma certification exam, which is higher than the national average of 91%. This shows that with proper training, systems and teams can expect strong results.

Clients who invest in Six Sigma certification build stronger teams and achieve better outcomes. If systems and teams want to learn more about the certification process or need help preparing, they can reach out for expert support.

Implementation

Challenges

Many organizations face obstacles when they try to implement Six Sigma. Systems and teams often encounter resistance to change, lack of expertise, and resource constraints. These challenges can slow progress or even stop improvement efforts. The table below shows common challenges and proven strategies to overcome them:

Challenge | How to Overcome |

|---|---|

Resistance to Change | Communicate benefits, involve employees early, and provide thorough training. |

Lack of Expertise | Invest in certified training, hire experienced practitioners, and develop internal champions. |

Resource Constraints | Start with pilot projects, focus on high-impact areas, and secure executive sponsorship. |

Sustaining Six Sigma Long-Term | Embed Six Sigma into company culture and use continuous improvement cycles. |

Misalignment with Goals | Align projects with strategic objectives and engage cross-functional teams. |

Data Collection Challenges | Use data management tools and clear protocols, and foster a data-driven culture. |

Setting Realistic Expectations | Set incremental milestones and highlight early successes. |

Systems and teams that address these challenges early see better results and higher engagement from clients and staff.

Success Factors

Organizations that achieve strong results with Six Sigma share several key success factors. Leadership commitment stands out as the most important. When top management supports Six Sigma, systems and teams receive the direction and resources they need. Effective project selection ensures that improvement efforts align with business goals and deliver measurable impact. Robust training programs equip employees with the right skills, while continuous monitoring helps sustain improvements.

Critical success factors include:

Leadership commitment and support from top management.

Effective project selection and prioritization.

Robust training and certification for all team members.

Continuous monitoring and improvement using clear metrics.

Other important factors involve manager involvement, early project wins, open communication, and fact-based decision making. Systems and teams that align Six Sigma with company strategy and maintain consistent communication see the greatest benefits. Clients who focus on these factors often achieve higher quality, efficiency, and customer satisfaction.

Tips

Systems and teams can improve their Six Sigma implementation by following practical tips used by successful organizations:

Foster a culture of continuous improvement throughout the organization.

Encourage collaboration across departments with regular meetings and shared tools like value stream mapping.

Align all teams with common goals focused on customer satisfaction and waste reduction.

Provide ongoing education and clear communication to keep everyone engaged.

Use Lean Six Sigma tools such as root cause analysis to identify and eliminate inefficiencies.

Pilot test solutions before full rollout to minimize risk.

Track progress with key performance indicators like defect rates, process efficiency, and customer satisfaction.

Set SMART goals (Specific, Measurable, Achievable, Relevant, Time-bound) for each project.

Address employee resistance with regular updates, recognition, and quick wins.

Integrate Lean principles to enhance process flow and reduce costs.

Clients who apply these tips see higher success rates and lasting improvements. Systems and teams that want to learn more about effective Six Sigma implementation can reach out for expert guidance.

Lean Six Sigma

Lean Principles

Lean principles guide systems and teams to deliver more value with fewer resources. These principles help organizations focus on what matters most to clients and remove anything that does not add value. Lean and Six Sigma work well together because both aim to improve quality and efficiency.

Focus on the Customer – Systems and teams define value from the customer’s perspective. This ensures every improvement meets real needs and expectations.

Map the Value Stream – Teams visualize all steps in a process to spot inefficiencies. This supports Six Sigma’s data-driven approach by making problems visible.

Manage and Improve Process Flow – Teams look for bottlenecks and root causes. They keep work moving smoothly, which matches Six Sigma’s goal of reducing variation.

Remove Non-value-added Steps and Waste – Teams cut out steps that do not help the customer. Lean’s waste elimination fits with Six Sigma’s focus on defect reduction.

Pursue Perfection – Teams strive for continuous improvement. They use feedback and data to get better over time.

Lean principles help systems and teams create processes that are faster, more reliable, and better aligned with customer needs.

Integration

Lean Six Sigma combines the strengths of both Lean and Six Sigma. Lean targets waste and process flow, while Six Sigma focuses on reducing defects and variation. Together, they create a powerful approach for systems and teams.

Aspect | Description |

|---|---|

Focus | Lean removes waste; Six Sigma reduces defects and variation. |

Approach | Lean Six Sigma uses DMAIC to guide systematic improvements. |

Tools | Teams use process mapping, control charts, FMEA, Kaizen, 5S, and Voice of the Customer. |

People | Training and involvement empower systems and teams to sustain improvements. |

Alignment | Improvements match real workflow and customer needs. |

Systems and teams use Lean Six Sigma to optimize both speed and quality. The DMAIC framework helps them measure, analyze, and control changes. This integration leads to high-performing operations and lasting results for clients.

Lean Six Sigma empowers systems and teams to solve problems at the root, making improvements that last.

Benefits

Organizations that use Lean Six Sigma see measurable gains in many areas. Systems and teams achieve faster processes, lower costs, and better quality for clients.

Benefit Area | Measurable Outcome | Description |

|---|---|---|

Production Cycle Time | Teams speed up manufacturing and increase capacity. | |

Manufacturing Costs | 50% decrease | Systems cut costs by removing waste and improving efficiency. |

Defect Reduction | Near 3.4 defects per million opportunities | Lean Six Sigma improves quality by combining waste elimination and defect control. |

Process Variation Control | Enhanced consistency | Teams achieve more reliable results than with Lean or Six Sigma alone. |

Continuous Improvement | Systematic use of DMAIC | Teams sustain progress through structured problem-solving. |

In healthcare, systems have reduced infection rates by 60% and improved compliance with best practices. Military repair teams increased output tenfold by streamlining their processes. These results show how Lean Six Sigma helps clients reach higher standards and deliver better outcomes.

Systems and teams that want to learn more about Lean Six Sigma or need help applying these methods can reach out for expert support.

Six Sigma drives real improvements in quality, efficiency, and business results for systems and teams. Organizations like Motorola, Amazon, and Ford report major gains after adopting Six Sigma, as shown below:

Organization | Key Outcomes | Quantitative Evidence |

|---|---|---|

Motorola | Defect reduction, cost savings | |

Ford Motors | Waste reduction, customer satisfaction | $2.19B waste cut; 5-point satisfaction rise |

3M | Pollution prevention, cost savings | $1B saved; 61% fewer emissions |

Mastering key tools and techniques helps teams sustain these results. Those interested in certification can choose from flexible options:

Certification Level | Duration | Learning Outcomes | Formats |

|---|---|---|---|

Yellow Belt | Fundamentals | Online, in-person | |

Green Belt | ~30 hours | Process improvement | Online, in-person |

Black Belt | ~40 hours | Lead projects | Online, in-person |

Systems and teams that invest in learning and continuous improvement build a culture of excellence. Clients who want to start or advance can explore self-study guides, accredited courses, or reach out for expert support.

FAQ

What is the main goal of Six Sigma?

Six Sigma aims to help systems and teams reduce defects and process variation. This method improves quality and efficiency. Clients see better results and higher satisfaction when they use Six Sigma tools and techniques.

How do systems and teams choose between DMAIC and DMADV?

Systems and teams use DMAIC for improving existing processes. They choose DMADV when designing new products or processes. The right choice depends on whether the goal is to fix or create.

Can Six Sigma work in service industries?

Yes, Six Sigma helps systems and teams in service industries like healthcare, finance, and retail. These teams use Six Sigma to reduce errors, improve customer service, and streamline operations.

What are the most important Six Sigma tools?

Key tools include SIPOC diagrams, control charts, Pareto charts, fishbone diagrams, and FMEA. Systems and teams use these tools to map processes, analyze data, find root causes, and manage projects.

How long does it take to get Six Sigma certified?

Certification time varies by belt level. Yellow Belt may take a few days. Green Belt and Black Belt require weeks or months. Systems and teams benefit from ongoing training and support.

Why do systems and teams need leadership support for Six Sigma?

Leadership support gives systems and teams the resources and direction needed for success. Leaders help set goals, remove barriers, and keep projects aligned with business objectives.

How can clients start using Six Sigma?

Clients can begin by learning the basics, joining a training program, or reaching out for expert guidance. Systems and teams often start with small projects and build skills over time.

What results can clients expect from Six Sigma?

Clients often see fewer defects, lower costs, and better customer satisfaction. Systems and teams that use Six Sigma report measurable improvements in quality and business performance.